Product Description

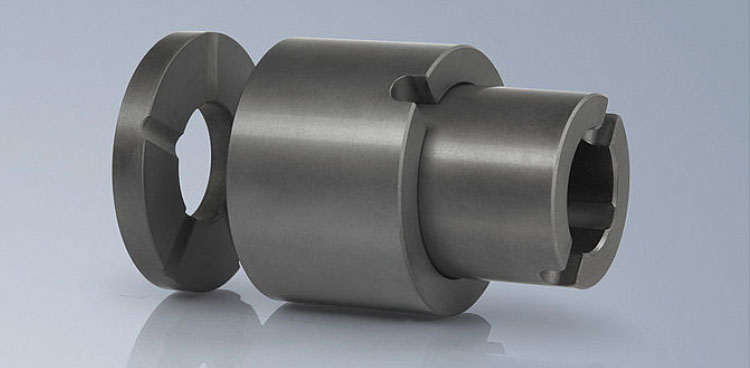

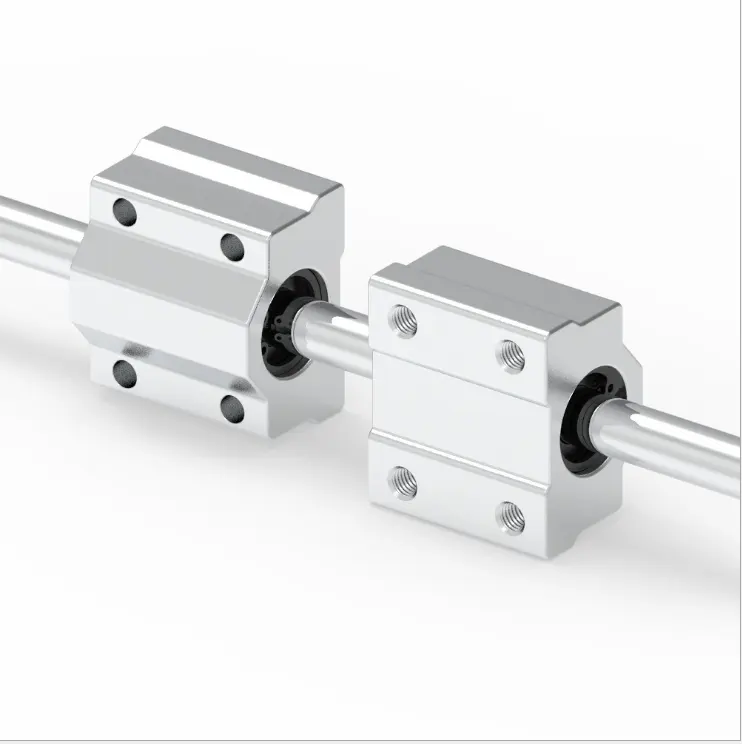

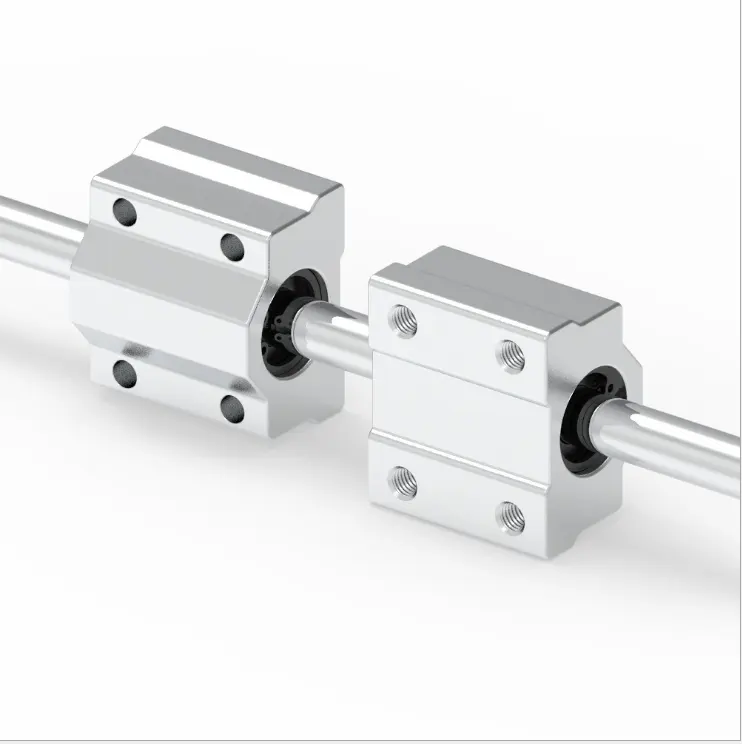

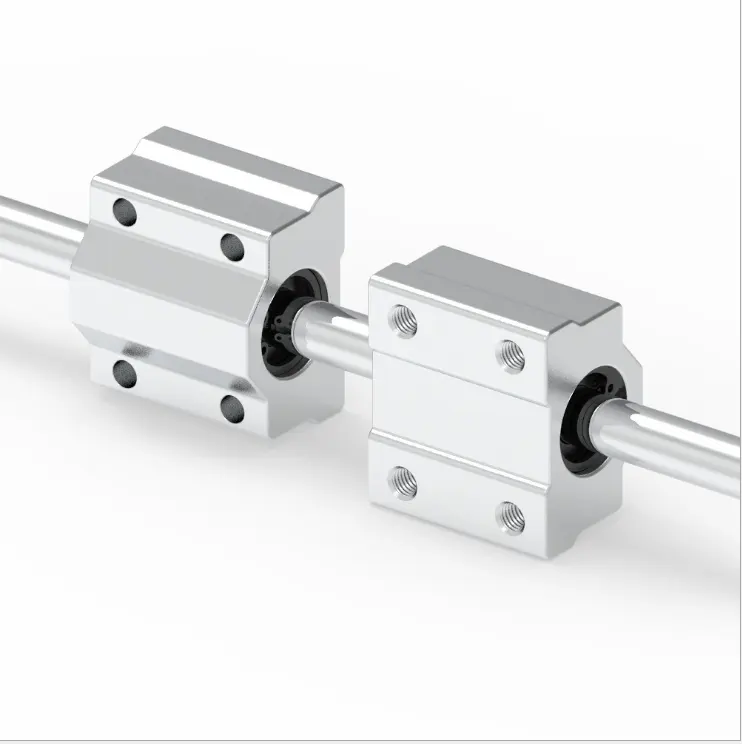

Product Name: Asian standard extended slider unit open bearing

Name: Open slider, Straight slider, box slider, lengthened straight slider, Aluminum slider, box unit, plain bearing, SBR… UU,,SBRL.. UU

Model: SBR slider, box opening slider

SBR10UU,SBR12UU,SBR16UU,SBR20UU,SBR25UU,SBR30UU,SBR35UU,SBR40UU,SBR50UU

SBRL slider, extended box type opening slider

SBR16LUU,SBR20LUU,SBR25LUU,SBR30LUU,SBR35LUU,SBR40LUU

Product General informatio

a, Low frictional linear motion

Steel balls are accurately guided by a retainer, so low frictional resistance and stable linear motion can be achieved.

Simple replacement of conventional plain bushings

It is easy to use Linear Bushings instead of conventional plain bushings, because both types are used with a round shaft, and no major redesign is necessary.

b, Wide variations

For each dimensional series, standard, adjustable clearance and open types are available with and without seals, so the best linear bushing for the application may be selected. In addition to the standard type, the high-rigidity long type is available. These types can be selected to suit the requirements in applications.

c, Miniature linear bushing LM Compact design

Miniature Linear Bushing is very small in size, allowing for compact assembly in machines and equipment.

d, High Reliability

ERSK linear bearing has very stringent quality control standards covering every production process. With proper lubrication and use,trouble-free operation for an extended period of time is possible.

e,Smooth Operation

The high efficiency of linear shaft is vastly superior to conventional shaft. The torque required is less than 30%. Linear motion can be easily changed from rotary motion. The linear bearings are moved very smoothly in the linear shaft.

f,High Durability

Rigidly selected materials, intensive heat treating and processing techniques, backed by years of experience,have resulted in the most durable linear bearings manufactured.

g,Easy interchangable

h,Easy maintenance

the linear rails can replace the base surface installation, the old wear parts (rails and blocks) can be replaced, reduce costs.

i,Easy installation

the linear rails and carriages can be changed easily, reduce material costs, reduce product prices, reduce product replacement costs and time.

Brand trademark registration

Yiboyuan (HangZhou) Precision Machinery Co., Ltd. is a professional manufacturer of linear motion products with many years of experience. And has its own registered brand YBYZ, we specialize in the production of linear bearings, plain bearings, shaft bearings, box sliders, self-lubricating copper sleeve. Good quality, competitive price. Our company is located in HangZhou City, ZheJiang Province. Close to HangZhou Port, ZheJiang Port.

Our products are widely used in precision machinery, fitness equipment, printing presses, packaging machines, medical and food machinery, textile machinery and other machinery and auxiliary equipment. Our products sell well in North America, Western Europe, Australia, Southeast Asia, the Middle East, South America and other regions.

Our packing:

* Industrial pakage

HangZhou City, ZheJiang Province.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Vacuum, Magnetically, Low Temperature, Corrosion Resistant, High Temperature, High Speed, High Hardness |

|---|---|

| Function: | Super |

| Flange Shape: | None |

| Shape: | Straight |

| Series: | SBR |

| Material: | Alloy |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Challenges of Lubricant Contamination in Sliding Bearings and Solutions

Lubricant contamination in sliding bearings can lead to various challenges that impact performance and longevity. Here are some challenges and solutions:

Challenge: Reduced Lubrication Effectiveness

Contaminants such as dust, dirt, moisture, and foreign particles can compromise the lubricant’s ability to provide effective lubrication between bearing surfaces.

Solution: Regular maintenance practices involving cleaning and relubrication help remove contaminants and restore the lubricant’s effectiveness. Proper seals and shields can also prevent contaminants from entering the bearing.

Challenge: Increased Friction and Wear

Contaminants in the lubricant can create abrasive particles that increase friction and accelerate wear on bearing surfaces.

Solution: Using high-quality, clean lubricants and implementing effective filtration systems can minimize the presence of contaminants, reducing friction and wear.

Challenge: Component Damage

Contaminants can cause pitting, scratching, and other damage to bearing surfaces, leading to decreased performance and potential bearing failure.

Solution: Regular inspections and cleaning routines are essential to prevent the accumulation of contaminants. Using lubricants with appropriate viscosity and additives can also help protect bearing surfaces.

Challenge: Increased Heat and Temperature

Contaminants can create heat and increase operating temperatures due to increased friction, which can negatively impact bearing performance.

Solution: Clean lubricants with proper viscosity and thermal stability are essential to dissipate heat effectively. Maintaining proper lubrication levels helps manage temperature rise.

Challenge: Corrosion

Moisture and certain contaminants can lead to corrosion of bearing surfaces, which compromises their structural integrity.

Solution: Proper storage and handling of bearings, as well as using corrosion-resistant lubricants, can mitigate the risk of corrosion. Seals and shields also provide additional protection against moisture ingress.

Challenge: Lubricant Breakdown

Contaminants and high operating temperatures can cause lubricants to degrade over time, reducing their lubricating properties.

Solution: Monitoring lubricant condition and replenishing or changing it at appropriate intervals helps maintain its effectiveness. Using lubricants with good oxidation resistance is also important.

Lubricant contamination in sliding bearings can significantly impact their performance and longevity. Implementing proper maintenance practices, using clean and suitable lubricants, and employing effective sealing mechanisms are key strategies to address these challenges and ensure optimal sliding bearing operation.

Benefits of Sliding Bearings in Low-Speed and Heavy-Load Applications

Sliding bearings offer significant advantages in low-speed and heavy-load applications, where their unique characteristics provide optimal performance. Some examples of scenarios where sliding bearings benefit such applications include:

- Mining Equipment: Sliding bearings are used in mining machinery such as crushers, mills, and conveyor systems. These applications often involve heavy loads and low speeds, where sliding bearings can provide robust support and reliable operation.

- Steel Mills: In steel production, sliding bearings are utilized in rolling mills and continuous casting machines. These operations require handling heavy loads and slow rotation speeds, making sliding bearings suitable for providing the necessary support.

- Hydraulic Systems: Sliding bearings are used in hydraulic cylinders, where slow and controlled movements are required for applications like construction machinery, material handling equipment, and heavy-duty presses.

- Cranes and Lifts: Sliding bearings are employed in the construction of cranes, elevators, and lifting platforms. These applications involve lifting and lowering heavy loads at controlled speeds, making sliding bearings crucial for smooth and reliable motion.

- Wind Turbines: Sliding bearings are used in the yaw and pitch systems of wind turbines. These systems need to handle the substantial weight of the turbine blades and operate at low speeds to optimize energy generation.

In these scenarios and more, sliding bearings provide the necessary support, stability, and durability required for low-speed and heavy-load applications.

Advantages of Sliding Bearings Compared to Other Bearings

Sliding bearings, also known as plain bearings or journal bearings, offer several advantages compared to other types of bearings. These advantages make them suitable for specific applications where their characteristics are beneficial:

- High Load-Carrying Capacity: Sliding bearings can handle high loads due to their larger contact area and distribution of pressure, making them suitable for heavy machinery and industrial equipment.

- Low Friction: Sliding bearings operate on the principle of sliding friction, which can result in lower frictional losses and energy consumption compared to rolling element bearings.

- Simplicity: Sliding bearings have a straightforward design with fewer components, reducing complexity and potential points of failure.

- Cost-Effectiveness: The simpler design and manufacturing process of sliding bearings can lead to lower production costs and maintenance expenses.

- Shock and Vibration Absorption: Sliding bearings can dampen shocks and vibrations due to their ability to accommodate misalignments and absorb dynamic forces.

- High-Temperature Applications: Some sliding bearings are capable of operating in high-temperature environments where other types of bearings might fail.

- Self-Lubrication: Some sliding bearings are designed with self-lubricating materials, reducing the need for external lubrication and maintenance.

- Noisiness: Sliding bearings often produce less noise than rolling element bearings, which can be advantageous in noise-sensitive applications.

- Corrosion Resistance: Sliding bearings made from materials such as bronze or plastic can offer better corrosion resistance in certain environments.

- Adaptability to Dirty Environments: Sliding bearings can perform well in dirty or contaminated environments where rolling element bearings might be more prone to failure due to debris.

However, it’s important to note that sliding bearings also have limitations, such as higher frictional heat generation, potential for stick-slip behavior, and limited suitability for high-speed applications. The choice between sliding bearings and other types of bearings depends on the specific requirements of the application and the trade-offs that need to be considered.

editor by CX 2024-05-15

China Professional Rod End Sliding Roller Thrust Special Cylindrical Bearings Group, Stieber, IKO, Fst/ Bearings for Machinery & Auto deep groove ball bearing

Product Description

About Cylindrical roller bearings:

1.Cylindrical roller bearings are separable bearings, installation and removal is very convenient.

2.Cylindrical roller bearings can withstand greater radial load, suitable for use in high speed applications.

3.Cylindrical roller bearings can be divided into single row, double row and multi-row cylindrical roller bearings and

other different structures.

4.Cylindrical roller bearings can be divided into PO, P6, P5, P4, P2 according to accuracy class.

Cylindrical roller bearing are of high load capacity and can operate at high speeds because they use rollers as their

rolling elements. They can therefore be used in applications involving heavy radial and impact loading.

The rollers are cylindrical in shape and crowned at the end in order to reduce the stress concentrations. They are also

suitable for applications that require high speed because the rollers are guided by CZPT which are either on the outer or inner ring.

| Product name | Cylindrical roller bearing |

| Place of Origin | China,ZheJiang |

| Structure | Roller Bearing |

| Material | Gcr15 Bearing steel |

| Delivery time | 5-15days depends on quantity needed |

| Service | OEM service, according to customer requirements |

| Quality | Large bearing capacity, fine mass |

Company Profile

In order to meet the needs of the masses of customers and improve the market competitiveness of our company,

we can provide OEM service according to our customers′ Needs. We have gained ISO9001 certificate, CE certificate,

GOST certificate and SGS certificate. Our target is to carry out the strategic investment along with the development

of market and need of new products. With our strategic, excellent products, top technology and outstanding service,

we sincerely expect cooperation with more customers and friends for a better future. Our main products include

spherical roller bearing, deep groove ball bearings, cylindrical roller bearings, spherical roller bearings, needle roller

bearings, ball bearing units, water pump bearings, automobile bearing, linear motion bearing, oil-less bearings,

bush and self-lubricating bearings, and non-standard bearings. Also, we supply bearings to our domestic peeling

machine factory and the machine exported to India, Malaysia and Russia, no any complaint from customer until now.

“zero defect, zero complaints” as the quality objective.

FAQ

Q: Are you trading company or manufacturer ?

A: We are a trading company specializing in exporting bearings.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the

goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge

Q.You provide free consultation service?

Yes, before, during and after order, anytime.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Product Name: | Cylindrical Roller Bearing |

|---|---|

| Characteristic: | High Precision |

| Advantage: | Large Bearing Capacity |

| Holder: | Copper and Iron Retainers |

| Quality: | High Quality |

| Rolling Body: | Roller Bearings |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Advancements in Sliding Bearing Technology

Recent years have witnessed significant advancements in sliding bearing technology, leading to improved performance, durability, and efficiency in various applications. Some notable developments include:

Self-Lubricating Materials: The use of advanced self-lubricating materials, such as composite polymers and solid lubricants, has reduced the need for external lubrication, enhancing maintenance-free operation.

Nano-Coatings: Nano-coatings with improved wear resistance and reduced friction have been applied to sliding bearings, extending their lifespan and optimizing performance in demanding environments.

Improved Friction Management: Advanced surface texturing and micro-grooving techniques have been employed to manage friction and reduce wear, contributing to smoother operation and increased efficiency.

Bearing Monitoring Systems: Integration of sensors and monitoring systems allows real-time tracking of bearing health, enabling predictive maintenance and reducing unexpected downtime.

Customization: Modern manufacturing techniques, such as 3D printing and precision machining, allow for customized sliding bearings tailored to specific applications, improving overall system performance.

Environmentally Friendly Solutions: Development of environmentally friendly lubricants and materials ensures compliance with regulations and minimizes the impact of sliding bearing technology on the environment.

High-Load Capacities: Advances in material science and engineering have led to sliding bearings with increased load-carrying capacities, making them suitable for heavy-duty applications.

Enhanced Wear Resistance: Improved material compositions and surface treatments have enhanced wear resistance, reducing the need for frequent replacements and maintenance.

Reduced Noise and Vibration: Innovations in design and materials have resulted in sliding bearings that produce less noise and vibration, contributing to quieter and more comfortable machinery operation.

Integration with IoT: Integration of sliding bearings into the Internet of Things (IoT) networks allows for remote monitoring and optimization of bearing performance.

Digital Twin Technology: Digital twin simulations are being used to model sliding bearing behavior, aiding in design optimization and performance prediction.

Efficiency in High-Temperature Environments: Advancements in heat-resistant materials have enabled sliding bearings to operate efficiently in high-temperature industrial applications.

These advancements collectively contribute to the evolution of sliding bearing technology, making them more reliable, durable, and adaptable to a wide range of industrial and commercial applications.

Maintenance Practices to Extend the Lifespan of Sliding Bearings

Proper maintenance is essential for maximizing the lifespan of sliding bearings and ensuring optimal performance. Here are specific practices that can help extend the life of sliding bearings:

Regular Lubrication: Adequate lubrication is crucial for minimizing friction and wear between sliding surfaces. Follow manufacturer recommendations for lubrication intervals and use the appropriate lubricants for the operating conditions.

Clean Environment: Keep the surrounding environment clean and free from dust, dirt, and contaminants. Regularly clean the machinery or equipment to prevent debris from entering the bearing area.

Seal Integrity: Ensure that bearing seals are in good condition to prevent contaminants from entering and lubricant from escaping. Replace damaged seals promptly to maintain proper protection.

Alignment and Mounting: Proper alignment and mounting of sliding bearings are critical to distribute loads evenly and prevent excessive wear. Follow manufacturer guidelines for installation procedures and torque specifications.

Regular Inspections: Schedule routine inspections to detect early signs of wear, damage, or misalignment. Visual inspections, temperature checks, and vibration analysis can help identify issues before they escalate.

Maintenance Records: Maintain detailed records of maintenance activities, including lubrication schedules, inspections, and replacements. This information can help track the condition of sliding bearings and plan maintenance tasks effectively.

Temperature Management: Control operating temperatures within recommended limits. Excessive heat can degrade lubricants and accelerate wear, while extreme cold can affect bearing performance.

Load Management: Avoid subjecting sliding bearings to loads beyond their specified capacities. Overloading can lead to premature wear and damage.

Training and Education: Ensure that personnel responsible for maintenance are adequately trained in proper procedures. Knowledgeable staff can perform maintenance tasks accurately and identify potential issues.

Timely Replacement: When wear or damage is detected that exceeds acceptable limits, replace sliding bearings promptly to prevent further damage to the machinery or equipment.

By implementing these maintenance practices, you can significantly extend the lifespan of sliding bearings, reduce downtime, and optimize the performance of machinery and equipment.

Common Applications and Industries of Sliding Bearings

Sliding bearings are utilized across a wide range of applications and industries due to their unique advantages. Some common applications and industries where sliding bearings are commonly used include:

- Automotive Industry: Sliding bearings are found in engines, transmissions, suspension systems, and various automotive components.

- Industrial Machinery: They are used in manufacturing equipment, conveyors, printing machines, and more.

- Power Generation: Sliding bearings are crucial in turbines, generators, and power transmission systems.

- Aerospace: They play a role in aircraft landing gear, control systems, and propulsion mechanisms.

- Marine: Sliding bearings are used in ship engines, propellers, and steering systems.

- Construction and Mining: They are found in heavy machinery, excavators, loaders, and construction equipment.

- Oil and Gas: Sliding bearings are used in drilling rigs, pumps, compressors, and refineries.

- Railway: They are employed in locomotives, train wheels, and rail systems.

- Medical Equipment: Sliding bearings are used in medical devices, imaging equipment, and surgical instruments.

- Textile Industry: They play a role in weaving machines, spinning frames, and looms.

- Food and Beverage: Sliding bearings are utilized in food processing equipment and packaging machinery.

- Renewable Energy: They are used in wind turbines, solar tracking systems, and other renewable energy applications.

Sliding bearings provide reliable support and smooth motion in various environments, making them essential components in a wide range of industries.

editor by CX 2024-04-25

China wholesaler Roller Customized Bicycle Sliding Window Rollers Bearings Bearing for Car Rolamento Hot double row ball bearing

Product Description

Product Description

Wheel hub bearings

The DAC type auto front wheel bearing is a double row angular contact ball bearing incorporating an integral outer ring and two separable inner rings; which is available either with seals or without seals. The auto wheel hub bearings can bear beavier axial and radial load.it is no need to adjust the inner clearance because it is already preserved in making.It was filled with Iubricating grease in high quality in the inner bearing,which could make the assemblage and usage easily.The range of the diameter of the inner ring is from 20 to 80mm and that of the outer ring is from 40 to 120mm.Now there are more than 300 kinds of this bearings.

Features and Benefits:

1. Low friction and running temperatures, low noise, and vibration

2. High running speeds

3. High quality and performance capabilities for your application

4. Accommodate radial loads and axial loads in both directions

5. Available with a variety of greases for most conditions, including food quality grease, high-temperature grease, and Solid Oil

6. Increased reliability and provide long bearing and lubricant service life

| Item No. | Dimensions | |||

| d | D | B | C | |

| DAC25525716 | 25 | 52 | 20.6 | 20.6 |

| DAC25520037 | 25 | 52 | 37 | 37 |

| DAC25550043 | 25 | 55 | 43 | 43 |

| DAC25560032 | 25 | 56 | 32 | 32 |

| DAC27600050 | 27 | 60 | 50 | 50 |

| DAC28610042 | 28 | 61 | 42 | 42 |

| DAC30600037 | 30 | 60 | 37 | 37 |

| DAC306500264 | 30 | 65 | 26.4 | 26.4 |

| DAC30650571 | 30 | 65 | 21 | 21 |

| DAC34620037 | 34 | 62 | 37 | 37 |

| DAC34640037 | 34 | 64 | 37 | 37 |

| DAC34660037 | 34 | 66 | 37 | 37 |

| DAC35640037 | 35 | 64 | 37 | 37 |

| DAC35650035 | 35 | 65 | 35 | 35 |

| DAC35660032 | 35 | 66 | 32 | 32 |

| DAC35660037 | 35 | 66 | 37 | 37 |

| DAC35680037 | 35 | 68 | 37 | 37 |

| DAC35725718 | 35 | 72.02 | 28 | 28 |

| DAC3572571 | 35 | 72.04 | 33 | 33 |

| DAC36680033 | 36 | 68 | 33 | 33 |

| DAC3672571 | 36 | 72.05 | 34 | 34 |

| DAC37720037 | 37 | 72 | 37 | 37 |

| DAC3772571 | 37 | 72.04 | 37 | 37 |

| DAC37740045 | 37 | 74 | 45 | 45 |

| DAC38720040 | 38 | 72 | 40 | 40 |

| DAC38725716/33 | 37.99 | 72.02 | 36 | 33 |

| DAC38745716/33 | 37.99 | 74.02 | 36 | 33 |

| DAC39680637 | 39 | 68.06 | 37 | 37 |

| DAC39720037 | 39 | 72 | 37 | 37 |

| DAC39720637 | 39 | 72.06 | 37 | 37 |

| DAC39740039 | 39 | 74 | 39 | 39 |

| Bearing Model | dXDXB ( mm ) | Weight /KG |

| DAC27600050 | 27*60*50 | 0.56 |

| DAC28580042 | 28*58*42 | 0.45 |

| DAC28610042 | 28*61*42 | 0.53 |

| DAC29530037 | 29*53*37 | 0.34 |

| DAC3050571 | 30*50*20 | 0.13 |

| DAC30540571 | 30*54*24 | 0.36 |

| DAC3 0571 030/25 | 30*55*30 | 0.39 |

| DAC3 0571 032 | 30*55*32 | 0.27 |

| DAC3 0571 042 | 30*58*42 | 0.48 |

| DAC30600037 | 30*60*37 | 0.42 |

| DAC30600337 | 30*60.3*37 | 0.42 |

| DAC3060037/34 | 30*60*37 | 0.36 |

| DAC30620032 | 30*62*32 | 0.36 |

| DAC30620037 | 30*62*37 | 0.42 |

| DAC30620038 | 30*62*38 | 0.43 |

| DAC30620044 | 30*62*44 | 0.44 |

| DAC30630042 | 30*63*42 | 0.47 |

| DAC30640037 | 30*64*37 | 0.47 |

| DAC30640042 | 30*64*42 | 0.49 |

| DAC30650571 | 30*65*21 | 0.27 |

| DAC306500264 | 30*65*26.4 | 0.36 |

| DAC30680045 | 30*68*45 | 0.52 |

| DAC307200302 | 30*72*30.2 | 0.31 |

| DAC30720037 | 30*72*37 | 0.8 |

| DAC32720045 | 32*72*45 | 0.6 |

| DAC32720034 | 32*72*34 | 0.6 |

| DAC34620037 | 34*62*37 | 0.41 |

| DAC34640037 | 34*64*37 | 0.43 |

| DAC34660037 | 34*66*37 | 0.41 |

| DAC34670037 | 34*67*37 | 0.44 |

| DAC35640037 | 35*64*37 | 0.41 |

Our Advantages

1. World-Class Bearing: We provide our customers with all types of indigenous bearing with world-class quality.

2. OEM or Non-Stand Bearings: Any requirement for Nonstandard bearings is Easily Fulfilled by us due to its vast knowledge and links in the industry.

3. Genuine products With Excellent Quality: The company has always proved the 100% quality products it provides with genuine intent.

4. After Sales Service and Technical Assistance: The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

5. Quick Delivery: The company provides just-in-time delivery with its streamlined supply chain.

SAMPLES

1. Samples quantity: 1-10 PCS are available.

2. Free samples: It depends on the Model No., material and quantity. Some of the bearings samples need client to pay samples charge and shipping cost.

3. It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1. MOQ: 10 PCS standard bearings.

2. MOQ: 1000 PCS customized your brand bearings.

OEM POLICY

1. We can printing your brand (logo, artwork)on the shield or laser engraving your brand on the shield.

2. We can custom your packaging according to your design

3. All copyright own by clients and we promised don’t disclose any info.

2. OEM or Non-Stand Bearings: Any requirement for Nonstandard bearings is Easily Fulfilled by us due to its vast knowledge and links in the industry.

3. Genuine products With Excellent Quality: The company has always proved the 100% quality products it provides with genuine intent.

4. After Sales Service and Technical Assistance: The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

5. Quick Delivery: The company provides just-in-time delivery with its streamlined supply chain.

FAQ

SAMPLES

1. Samples quantity: 1-10 PCS are available.

2. Free samples: It depends on the Model No., material and quantity. Some of the bearings samples need client to pay samples charge and shipping cost.

3. It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1. MOQ: 10 PCS standard bearings.

2. MOQ: 1000 PCS customized your brand bearings.

OEM POLICY

1. We can printing your brand (logo, artwork)on the shield or laser engraving your brand on the shield.

2. We can custom your packaging according to your design

3. All copyright own by clients and we promised don’t disclose any info.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Customized |

|---|---|

| Certification: | ISO |

| Standard Parts: | Yes |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Role of Sliding Bearings in Vibration Dampening and Shock Absorption Applications

Sliding bearings are essential components in applications where vibration dampening and shock absorption are critical. Here’s how they fulfill this role:

Vibration Dampening:

In various industrial processes and equipment, vibrations can lead to reduced performance, increased wear and tear, and even structural damage. Sliding bearings help dampen vibrations by providing a cushioning effect between moving components. The design of sliding bearings allows them to absorb and dissipate vibrations, preventing them from propagating throughout the machinery.

Shock Absorption:

Heavy machinery and equipment often experience sudden impacts or shocks due to sudden loads or external forces. Sliding bearings with their ability to absorb shocks and impacts help protect machinery from damage. They act as buffers that absorb and distribute the energy generated by these shocks, preventing it from causing harm to other components or the machinery structure.

Isolation of Vibrations:

Sliding bearings can be strategically placed in machinery to isolate specific components or sections from vibrations. This isolation helps maintain the stability and accuracy of delicate components that might be sensitive to vibrations, such as precision instruments or measurement devices.

Enhanced Comfort:

In applications involving human interaction, such as vehicles or industrial tools, sliding bearings contribute to user comfort. By reducing vibrations and shocks transmitted to the operator or occupants, sliding bearings improve the overall user experience and reduce operator fatigue.

Prevention of Resonance:

Resonance is a phenomenon where vibrations can be amplified due to the natural frequencies of the components. Sliding bearings help prevent resonance by providing damping properties that counteract the amplification effect. This is crucial in applications where precise control and stability are required.

In conclusion, sliding bearings play a vital role in applications requiring vibration dampening and shock absorption. Their ability to dampen vibrations, absorb shocks, isolate vibrations, enhance comfort, and prevent resonance contributes to the efficient and reliable operation of machinery and equipment in various industries.

Contribution of Sliding Bearings to Hydraulic Systems and Pumps

Sliding bearings play a crucial role in ensuring the smooth and efficient operation of hydraulic systems and pumps. Here’s how they contribute to these applications:

Load Distribution: Sliding bearings distribute the axial and radial loads generated by hydraulic components, such as pistons and impellers, across their surfaces. This helps prevent localized stress and ensures uniform load distribution, enhancing the overall stability of the system.

Reduced Friction: Sliding bearings minimize friction between moving parts within hydraulic systems and pumps. This friction reduction leads to lower energy consumption and less heat generation, contributing to improved efficiency and reduced wear and tear.

Fluid Film Formation: Properly lubricated sliding bearings create a fluid film between their surfaces. This fluid film serves as a barrier that prevents direct contact between the bearing surfaces, reducing friction and wear and enabling smooth movement even at high speeds.

Sealing Function: Sliding bearings often incorporate seals to prevent the ingress of contaminants, such as dirt and moisture, into the hydraulic system or pump. This sealing function helps maintain the integrity of the system’s components and extends their lifespan.

Alignment Compensation: In hydraulic systems, sliding bearings can compensate for minor misalignments between components, such as shafts and impellers. This ability to accommodate misalignment contributes to reduced stress and longer component life.

Quiet Operation: Sliding bearings help dampen vibrations and noise generated during the operation of hydraulic systems and pumps. This contributes to quieter and more comfortable working environments.

Customization: Sliding bearings can be designed and customized to meet the specific requirements of different hydraulic systems and pumps. This adaptability ensures optimal performance and longevity.

Overall, sliding bearings enhance the reliability, efficiency, and longevity of hydraulic systems and pumps by minimizing friction, distributing loads, facilitating smooth movement, and providing protection against contaminants. Their contribution is essential to achieving consistent and precise fluid transfer and power generation in various industrial applications.

Sliding Bearings and Their Applications

Sliding bearings, also known as plain bearings or journal bearings, are a type of bearing that operate on the principle of sliding friction between two surfaces. They are utilized in various applications where rotational or linear movement needs to be facilitated while minimizing friction and wear. Here are some common applications of sliding bearings:

- Automotive Industry: Sliding bearings are widely used in engines and transmissions of vehicles to support rotating shafts and provide low-friction movement.

- Industrial Machinery: They are employed in industrial equipment such as pumps, compressors, and turbines, where they help in reducing friction and ensuring smooth operation.

- Aerospace: Sliding bearings are crucial components in aircraft engines, landing gear systems, and various aerospace mechanisms to provide reliable and low-wear motion.

- Power Generation: In power plants, sliding bearings are found in turbines, generators, and other rotating equipment to facilitate movement with minimal energy loss.

- Marine Applications: They are used in ship engines, propellers, and other marine equipment, providing durability in harsh marine environments.

- Construction Equipment: Sliding bearings are used in construction machinery like cranes and excavators to support heavy loads and ensure smooth movement.

- Heavy Industry: Various heavy industries, including mining and steel production, rely on sliding bearings for their robustness and ability to handle heavy loads.

- Home Appliances: Sliding bearings are found in appliances like washing machines and refrigerators, facilitating the movement of rotating parts.

- Medical Devices: Some medical devices use sliding bearings for their precision and low friction, ensuring accurate movement in equipment like medical scanners and robotic surgical systems.

Sliding bearings are chosen for applications where simplicity, cost-effectiveness, and reliable performance are essential. They come in different designs, such as plain cylindrical bearings, thrust bearings, and spherical bearings, to suit various motion requirements. Regular maintenance and proper lubrication are necessary to ensure the longevity and optimal performance of sliding bearings in their respective applications.

editor by CX 2024-04-04

China Best Sales Linear Sliding Unit Lm6uu Linear Ball Bearings for CNC Machine 3D Printer ball bearing

Product Description

Product Description

- Bearing structure: consists of outer cylinder, retainer, balls, side seals;

- Premium grade raw material: GCr15 bearing steel cylinder, G10 class precision ball, PA66 plastic retainer;

- Cylinder metal body is heat treated and hardened to enhance to the rigidity and working life;

- Both the inner bore and outer cylinder surface are ground several procedures to guarantee the precision;

- Completely washed by the super sonic washing machine, pre-lubricated;

- Main features: high precision and rigidity, low friction, ease of assembly and replacement, good interchangeability;

- Good quality at affordable rates, price is very economic and nice;

- Ideal transmission component for linear motion movement, widely used in CNC machines, factory automation, industrial machines, electric tools, textile machines, fitting equipment, etc.;

- Wide size range for option, models including(special size has to be customized):

LM3, LM4, LM5UU, LM6UU, LM8SUU, LM8UU, LM10UU, LM12UU, LM13UU, LM16UU, LM20UU, LM25UU, LM30UU, LM35UU, LM40UU, LM50UU, LM60UU, LM80UU, LM100UU, LM120UU, LM150UU, etc.

Product Parameters

Detailed Photos

Certifications

Packaging & Shipping

1.According to the quantity and the ship method of your order, we will choose the best packing ways.

2.For example, if the products shipped by TNT,DHL,FedEx, the goods would be packed by paper carton for economic delivery. As bulk order shipped by sea, the goods would be packed by wooden carton.

Our Advantages

FAQ

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Q1:Who we are?

We are the factory based in ZHangZhoug,China,start from 2007 sell to all over the.world.the factory area is around 45000 square meters.we have 900 employees.

Q2: Do you have a catalogue?

Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q3: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q4 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.

Q5: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the

shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

Recommend product

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Magnetically, Corrosion Resistant, High Speed, High Precision |

|---|---|

| Function: | Super |

| Flange Shape: | Oval |

| Shape: | Flange |

| Series: | LM |

| Material: | Bearing Steel |

| Samples: |

US$ 16.8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Differences Between Plain Sliding Bearings and Self-Lubricating Bearings

Plain sliding bearings and self-lubricating bearings are two distinct types of bearings used in various applications. Here are the key differences between them:

Plain Sliding Bearings:

- Plain sliding bearings, also known as bushings, are simple bearing components that consist of a cylindrical sleeve made of a bearing material.

- These bearings require external lubrication, such as grease or oil, to reduce friction and wear between the bearing and the shaft.

- Regular maintenance and lubrication are essential to ensure proper operation and longevity.

- Plain sliding bearings are cost-effective and suitable for applications where lubrication can be easily provided.

- They are commonly used in low-speed and low-load applications, where the shaft slides within the bearing.

Self-Lubricating Bearings:

- Self-lubricating bearings, also known as maintenance-free bearings, are designed to operate without the need for external lubrication.

- These bearings incorporate solid lubricants, such as graphite, PTFE (polytetrafluoroethylene), or other additives, directly into the bearing material.

- The solid lubricants are released gradually as the bearing operates, reducing friction and providing a consistent lubricating film.

- Self-lubricating bearings are ideal for applications where frequent maintenance or lubrication is impractical or not feasible.

- They are suitable for both low-load and high-load applications, as the self-lubricating properties help extend the bearing’s service life.

In summary, plain sliding bearings require external lubrication and are suitable for applications where lubrication can be provided, while self-lubricating bearings incorporate solid lubricants and operate without the need for regular maintenance. The choice between these two types depends on factors such as the application’s operating conditions, maintenance requirements, and budget considerations.

Impact of Materials on Sliding Bearing Performance and Durability

The choice of materials used in sliding bearings significantly influences their performance, longevity, and suitability for specific applications. Different materials offer varying characteristics that affect factors such as friction, wear resistance, load capacity, and corrosion resistance. Here are some common materials and their effects:

- Bronze Bearings: Bronze bearings, often made from bronze alloys, offer good load-carrying capacity and resistance to wear. They are suitable for applications with moderate to heavy loads and low to moderate speeds. Bronze bearings also have good heat dissipation properties.

- Steel Bearings: Steel bearings, particularly those made from stainless steel, provide excellent corrosion resistance and are suitable for applications exposed to harsh environments or moisture. Steel bearings are often used in marine and food processing industries.

- Polymer Bearings: Polymer bearings, such as those made from materials like PTFE (polytetrafluoroethylene) or nylon, offer low friction and self-lubricating properties. They are suitable for applications where minimizing friction and wear is critical.

- Composite Bearings: Composite bearings combine different materials to achieve specific performance characteristics. For instance, they might feature a polymer matrix with embedded reinforcing fibers for improved load capacity and wear resistance.

- Graphite Bearings: Bearings with graphite as a lubricating element can operate without additional lubrication in certain conditions, reducing maintenance needs and offering self-lubricating properties.

The selection of materials should consider factors such as the application’s operating conditions, load requirements, speed, temperature, and the presence of corrosive substances. The right material choice ensures optimal performance, durability, and minimal maintenance for sliding bearings.

Common Applications and Industries of Sliding Bearings

Sliding bearings are utilized across a wide range of applications and industries due to their unique advantages. Some common applications and industries where sliding bearings are commonly used include:

- Automotive Industry: Sliding bearings are found in engines, transmissions, suspension systems, and various automotive components.

- Industrial Machinery: They are used in manufacturing equipment, conveyors, printing machines, and more.

- Power Generation: Sliding bearings are crucial in turbines, generators, and power transmission systems.

- Aerospace: They play a role in aircraft landing gear, control systems, and propulsion mechanisms.

- Marine: Sliding bearings are used in ship engines, propellers, and steering systems.

- Construction and Mining: They are found in heavy machinery, excavators, loaders, and construction equipment.

- Oil and Gas: Sliding bearings are used in drilling rigs, pumps, compressors, and refineries.

- Railway: They are employed in locomotives, train wheels, and rail systems.

- Medical Equipment: Sliding bearings are used in medical devices, imaging equipment, and surgical instruments.

- Textile Industry: They play a role in weaving machines, spinning frames, and looms.

- Food and Beverage: Sliding bearings are utilized in food processing equipment and packaging machinery.

- Renewable Energy: They are used in wind turbines, solar tracking systems, and other renewable energy applications.

Sliding bearings provide reliable support and smooth motion in various environments, making them essential components in a wide range of industries.

editor by CX 2024-03-30

China Professional Windows Sliding Gearbox Skateboard Roller Skate Windows Doors Chrome Steel Gcr15 Stainless Steel 7*22*7 627 Deep Groove Ball Bearings bearing example

Product Description

Product Parameters

| Product Name | Deep Groove Ball Bearings | |

| Brand Name | NMN | |

| Material | Chrome Steel GCr15 Stainless Steel Ceramic Nylon | |

| Cage | Steel Brass Nylon | |

| Weight(Kg) | 0.013 | |

| Clearance | C0 C2 C3 C4 C5 | |

| Seals Type | Open Z 2Z 2RS Znr 2RS1 2rsh 2rsl 2znr | |

| Precision Grade | P0 P6 P5 P4 P2 | |

| Vibration | V1 V2 V3 V4 | |

| Quality | ABEC1, 3, 5, 7,9 | |

| Load Rating(kN) | Cr | 3.35 |

| Cor | 1.40 | |

| Limiting Speed | Grease | 34000 |

| Oil | 26000 | |

| Serice | OEM ODM | |

| Sample | Available | |

| Port | HangZhou/ZheJiang | |

Product Details

Single row deep groove ball bearings are used in a wide variety of applications, they are simple in design, non-separable, suitable for high speeds and are robust in operation, and need little maintenance. Deep raceway grooves and the close conformity between the raceway grooves and the balls enable deep groove ball bearings to accommodate axial loads in both directions, in addition to radial loads.

627 bearing has the advantages of low noise, low friction and high speed, and is equipped with sealing cover, grease, etc., to extend the life of the product.

We provide OEM, ODM and other services, and provide you with relevant consulting information to help you with bearing selection, clearance configuration, product life and reliability analysis. We offer localized shipping solutions to save your shipping costs.

We can provide free samples, can accept custom LOGO or drawings, can design packaging according to requirements.

Bearing Models

| Number | Specifiction | Load Rating (KN) | Limiting Speed (r/min) | Weight(Kg/pc) | |||||

| d(mm) | D(mm) | B(mm) | r(mm) | Cr | Cor | Grease | Oil | ||

| 604 | 4 | 12 | 4 | 0.2 | 0.9 | 0.36 | 43000 | 51000 | 0.002 |

| 605 | 5 | 14 | 5 | 0.2 | 1.33 | 0.505 | 39000 | 46000 | 0.0035 |

| 606 | 6 | 17 | 6 | 0.3 | 2.19 | 0.865 | 30000 | 38000 | 0.006 |

| 607 | 7 | 19 | 6 | 0.3 | 2.24 | 0.91 | 28000 | 3600 | 0.008 |

| 608 | 8 | 22 | 7 | 0.3 | 3.35 | 1.4 | 26000 | 34000 | 0.012 |

| 609 | 9 | 24 | 7 | 0.3 | 3.4 | 1.45 | 22000 | 30000 | 0.014 |

| 6000 | 10 | 26 | 8 | 0.3 | 4.55 | 1.96 | 20000 | 28000 | 0.019 |

| 6001 | 1 | 28 | 8 | 0.3 | 5.1 | 2.39 | 19000 | 26000 | 0.571 |

| 6002 | 15 | 32 | 9 | 0.3 | 5.6 | 2.84 | 18000 | 24000 | 0.03 |

| 6003 | 17 | 35 | 10 | 0.3 | 6.8 | 3.35 | 17000 | 22000 | 0.039 |

| 6004 | 20 | 42 | 12 | 0.6 | 9. | 5.05 | 1000 | 19000 | 0.069 |

| 6005 | 25 | 47 | 12 | 0.6 | 10.1 | 5.85 | 13000 | 17000 | 0.08 |

| 6006 | 30 | 55 | 13 | 1.0 | 13.2 | 8.3 | 12000 | 15000 | 0.116 |

| 6007 | 35 | 62 | 14 | 1.0 | 16 | 10.3 | 10000 | 13000 | 0.155 |

| 6008 | 40 | 8 | 15 | 1.0 | 16.8 | 11.5 | 8000 | 11000 | 0.185 |

| 6009 | 45 | 5 | 16 | 1.0 | 21 | 15.1 | 7200 | 9000 | 0.231 |

| 6571 | 50 | 80 | 16 | 1.0 | 21.8 | 16.6 | 6400 | 7800 | 0.25 |

| 6011 | 55 | 90 | 18 | 1.1 | 28.3 | 21.2 | 5700 | 7000 | 0.362 |

| 6012 | 60 | 95 | 18 | 1.1 | 29.5 | 23.2 | 5000 | 6300 | 0.385 |

| 6013 | 65 | 100 | 18 | 1.1 | 31.9 | 25 | 4800 | 6100 | 0.44 |

| 6014 | 70 | 110 | 20 | 1.1 | 39.7 | 31 | 4600 | 5800 | 0.6 |

| 6015 | 75 | 115 | 20 | 1.1 | 41.6 | 33.5 | 4400 | 5600 | 0.64 |

| 6016 | 80 | 125 | 22 | 1.1 | 47.5 | 40 | 4300 | 5500 | 0.854 |

| 6017 | 85 | 130 | 22 | 1.1 | 49.5 | 43 | 200 | 5300 | 0.89 |

| 6018 | 90 | 140 | 24 | 1.5 | 58 | 49.5 | 4000 | 5100 | 1.02 |

| 624 | 4 | 13 | 5 | 0.2 | 1.31 | 0.49 | 36000 | 45000 | 0.0032 |

| 625 | 5 | 16 | 5 | 0.3 | 1.76 | 0.68 | 32000 | 40000 | 0.0048 |

| 626 | 6 | 19 | 6 | 0.3 | 2.34 | 0.885 | 28000 | 36000 | 0.0081 |

| 627 | 7 | 22 | 7 | 0.3 | 3.35 | 1.40 | 26000 | 34000 | 0.013 |

| 628 | 8 | 24 | 8 | 0.3 | 4.00 | 1.59 | 24000 | 32000 | 0.017 |

| 629 | 9 | 26 | 8 | 0.3 | 4.55 | 1.96 | 22000 | 40000 | 0.0048 |

Packaging & Shipping

·Plastic rolling packing + Plastic bag + Paper carton

·Single Box + Plastic rolling packing + Plastic bag + Paper carton+pallet

·According to customer requirement

Applications

About Us

ZheJiang CZPT Bearing Group is a professional bearing manufacturer and exporter in China. We have been engaged in bearing industry for 20 years. Our company is specialized in producing Deep Groove Ball Bearings, Tapered Roller Bearings, Spherical Roller Bearings and Special Bearings in accordance with Customers’ designs.Our bearings has been widely applied into agricultural equipments, home appliances, power equipments, machine tools, automotives and engineering machinery, etc.

Our production is strictly executed with ISO9001 and ISO14001. Our products are mainly exported to Singapore, South Kora, Vietnam, Thailand, Turkey, Pakistan, Australia, Polan, France, UK, South America, USA, South Africa and other countries and regions of the world, with great public praise of high quality and reasonable price.

Company Profile

FAQ

1.Q:Could you supply free sample of bearing for our test?

A:Yes. Please afford the express fee and we will send you the sample within your first order.

2.Q:Sample time?

A:Within 3-4 days.

3.Q:Are you a factory or a Trade Company for Bearing ?

A:We are the factory.

4.Q:Whether you could make your products by our color?

A:Yes, The color of products can be customized if you can meet our MOQ.

5.Q:Could you accept OEM and customize?

A:Yes, OEM and ODM are accepted and we can customize for you according to sample or drawing.

6.Q:Do you have stocks?

A:Yes, most of the bearings showing on alibaba are in stock,especialy big bearings.

We sincerely hope we can build a long term relationship with all the clients and we also have great confidence in cooperating with every potential customer by most premium service and competitive price.

Welcome your inquiry and welcome your visit.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | Nmn |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Samples: |

US$ 0.01/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Improvement of Heavy Machinery Operation with Sliding Bearings

Sliding bearings play a crucial role in enhancing the operation of heavy machinery, such as mining equipment. Here’s how they contribute:

Reduced Friction and Wear:

Sliding bearings are designed to minimize friction between moving parts. In heavy machinery, where components are subjected to substantial loads and harsh conditions, reducing friction is essential to prevent premature wear and damage. Sliding bearings help distribute loads evenly and provide a smooth surface for components to slide against, reducing the risk of friction-induced failures.

Increased Durability:

The robust construction and materials used in sliding bearings make them well-suited for heavy machinery applications. They can withstand the heavy loads, impacts, and vibrations commonly encountered in mining equipment. Their durability contributes to the overall reliability and longevity of the machinery.

Improved Efficiency:

Efficiency is critical in heavy machinery to maximize productivity while minimizing energy consumption. Sliding bearings contribute to improved efficiency by reducing energy losses due to friction. With lower friction, machinery components can move more freely, requiring less energy to overcome resistance.

Resistance to Contaminants:

Mining environments are often filled with dust, dirt, and debris that can infiltrate machinery components. Sliding bearings are designed to operate effectively even in contaminated conditions. Their design and materials help prevent the intrusion of contaminants, reducing the risk of premature wear and component failure.

Enhanced Load Distribution:

Heavy machinery, especially in mining, experiences dynamic and uneven loads. Sliding bearings help distribute these loads evenly across surfaces, preventing localized stress concentrations. This load distribution contributes to the machinery’s overall structural integrity and minimizes the risk of catastrophic failures.

In conclusion, sliding bearings are integral to the efficient and reliable operation of heavy machinery in industries like mining. Their ability to reduce friction, enhance durability, improve efficiency, resist contaminants, and distribute loads makes them invaluable components for ensuring the smooth functioning of mining equipment.

Enhancing Efficiency of Marine Propulsion Systems with Sliding Bearings

Sliding bearings play a crucial role in enhancing the efficiency of marine propulsion systems and various ship components. Here’s how sliding bearings contribute to the efficiency of maritime applications:

Reduced Friction: Sliding bearings are designed to minimize friction between moving parts. In marine propulsion systems, such as propeller shafts and stern tubes, reduced friction results in less energy loss and improved fuel efficiency.

Smooth Operation: Sliding bearings provide smooth and controlled movement of rotating or linear components. In marine applications, this smooth operation translates to improved maneuverability, reduced vibrations, and enhanced overall performance.

Load Distribution: Sliding bearings distribute loads evenly across bearing surfaces. This even distribution helps prevent localized wear and reduces the risk of premature failure, ensuring reliable operation of ship components.

Resistance to Harsh Environments: Marine environments expose equipment to corrosive saltwater, extreme temperatures, and harsh weather conditions. Sliding bearings are often designed with materials and coatings that offer corrosion resistance and durability, ensuring longevity even in challenging maritime settings.

Enhanced Lubrication: Lubrication is vital for reducing wear and friction in sliding bearings. Many marine applications use advanced lubrication systems that optimize the distribution of lubricants, further reducing friction and improving efficiency.

Space Efficiency: Sliding bearings are compact and require minimal space, making them suitable for marine systems where space is limited. This efficient use of space is particularly important in ship design and layout.

Customization for Specific Needs: Sliding bearings can be tailored to meet the specific requirements of different ship components. This customization ensures that bearings are optimized for their intended functions, further contributing to efficiency.

Reduced Maintenance: Properly designed sliding bearings require less maintenance compared to some other types of bearings. This reduced maintenance need translates to less downtime and increased operational efficiency for marine vessels.

Optimized Performance: Overall, the efficient and reliable performance of sliding bearings in marine propulsion systems and ship components leads to improved energy efficiency, reduced operational costs, and extended service life of the equipment.

By incorporating sliding bearings into marine applications, shipbuilders and operators can achieve enhanced efficiency, reliability, and sustainability in their operations.

Design Principles and Functions of Sliding Bearings

Sliding bearings, also known as plain bearings or journal bearings, operate on the principle of providing a low-friction interface between two moving surfaces. The design of sliding bearings is based on creating a film of lubrication between the bearing surface and the shaft or journal it supports. This film of lubrication separates the two surfaces and minimizes direct metal-to-metal contact, reducing friction and wear.

The main components and design principles of sliding bearings include:

- Bearing Material: Sliding bearings are typically made from materials with good wear resistance and self-lubricating properties, such as bronze, brass, or various polymers. These materials help reduce friction and prevent excessive wear.

- Lubrication: Lubrication is crucial for the proper functioning of sliding bearings. It can be provided by an external lubricant, solid lubricants embedded in the bearing material, or a combination of both. The lubrication forms a protective layer that reduces direct contact and minimizes friction.

- Clearance: Sliding bearings are designed with a specific clearance between the bearing and the shaft to accommodate the lubricating film and allow for proper movement. This clearance prevents seizing and binding of the bearing.

- Load Distribution: The design of sliding bearings ensures that the load is distributed over a larger surface area to prevent excessive stress on any single point. This feature is essential for handling heavy loads in industrial applications.

- Alignment and Misalignment: Sliding bearings can tolerate small misalignments between the bearing and the shaft. This flexibility allows them to accommodate minor shifts caused by thermal expansion, vibration, or other factors.

- Heat Dissipation: Sliding bearings can generate frictional heat during operation. Proper design includes features to facilitate heat dissipation and prevent overheating that could lead to premature wear.

- Application-Specific Design: The design of sliding bearings can vary based on the specific application requirements, including load capacity, speed, operating temperature, and environmental conditions.

The functions of sliding bearings include providing support to rotating or sliding shafts, reducing friction, absorbing and distributing loads, allowing for misalignment, and offering smooth movement even in dirty or contaminated environments. Sliding bearings are commonly used in various industrial machinery and equipment, including engines, pumps, conveyors, and manufacturing equipment.

Overall, the design principles and functions of sliding bearings make them suitable for applications where low friction, durability, load-bearing capacity, and adaptability to varying conditions are essential.

editor by CX 2024-03-27

China manufacturer China Deep Groove Ball Bearings Small Size Bearing 626 for Sliding Door Window with high quality

Product Description

Product features

Deep groove ball bearing is a common rolling bearing, its inner ring and outer ring are both spherical, can bear radial and axial load, suitable for high-speed rotation and low noise occasions. The following are more introductions of deep groove ball bearings:

Structure type: The structure types of deep groove ball bearings include single-row, double-row and four-point contact and other types. Among them, single-row deep groove ball bearings are the most common, and the spherical raceway between the inner and outer rings enables the bearing to withstand radial and axial loads. Double-row deep groove ball bearings have a higher load capacity and are suitable for occasions that need to bear large radial and axial loads. Four-point contact deep groove ball bearings can withstand greater radial and axial loads, and can also withstand a certain tilting moment.

Material selection: The material selection of deep groove ball bearings includes steel, stainless steel, ceramics and other materials. Among them, steel deep groove ball bearings have good wear resistance and strength and are suitable for most industrial applications. Stainless steel deep groove ball bearings have good corrosion resistance and are suitable for humid and corrosive environments. Ceramic deep groove ball bearings have good wear resistance and corrosion resistance, and are suitable for high-speed rotation and high-temperature environments.

Dimensions: Deep groove ball bearings are available in various sizes, ranging from small to large. Generally speaking, the inner diameter of deep groove ball bearings ranges from 1 mm to 500 mm, the outer diameter ranges from 3 mm to 800 mm, and the thickness ranges from 1 mm to 200 mm. Appropriate size specifications can be selected according to the needs of different equipment.

Scope of application: deep groove ball bearings are widely used in mechanical equipment, automobiles, motors, instruments, household appliances and other fields. For example, deep groove ball bearings can be used between the rotor and stator in motors, in hubs and transmission systems in automobiles, in transmission systems and support systems in mechanical equipment, etc.

Advantages: Deep groove ball bearings have the advantages of simple structure, convenient use, wear resistance and low noise. At the same time, the contact area between the ball and the raceway of the deep groove ball bearing is small, so the friction coefficient is small, which can reduce energy loss and improve mechanical efficiency.

In short, deep groove ball bearings are a common rolling bearing with the advantages of simple structure, convenient use, wear resistance, low noise, etc., and are suitable for mechanical equipment, automobiles, motors, instruments, household appliances and other fields.

Company Profile

ZheJiang Jieyi Bearing Co., Ltd. is a more than 20-year history of bearing trading company. We are located in the biggest bearing town in China–Yiandian Town.

Our products include: Deep Groove Ball Bearings, Self-aligning Ball Bearings, Spherical Bearings, Tapered Roller Bearings, Cylindrical Roller Bearings, Needle Roller Bearings, Self-aligning Roller Bearings, Angular Contact Ball Bearings, Thrust Ball Bearings and Trust Roller Bearings and Special Bearings.

Jieyi Bearing also provides OEM service, such as bearing quality, noise level, grease brand, packing method, etc. We have enough OEM experience, and have a complete OEM manual for customer reference.

Products have been selling well in the American, French, Spanish, Austria, Italian, the U. A. E. Saudi, Pakistan, India, and Brizal markets.

With over 20 years′ experience in bearings market, Jieyi Bearing have built up good relationship with all of our customers and quality factory. We always get satisfactory feedback from our customers because of the high quality products and good OEM service. We always supply the quality, stable, economical bearings and proper technical services.

Jieyi Bearing has advanced quality testing and inspecting equipment, to guarantee product quality meets customers’ demand. Annually our company′s export over 10 million dollars.

To service dear customers at the fastest speed, we built a great Warehouse to stock bearings, so as to ship your required bearings fast. Inside of the bearing warehouse, there is all sourcing of bearing stock, with all kinds of bearings, over 10000 types.

Welcome to people of various enterprises with advance!

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory and trading company.

Q: How long is your delivery time?

A: Within 7 days with stock. 15-30 days for 1 container to OEM brand following your request

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge, freight cost need to be charged.

Q: What is your payment term?

A: We accept 30% TT advance ,70% balance against the bill loading copy. Also 100% L/C is ok.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Ball Bearings |

|---|---|

| The Number of Rows: | Double |

| Outer Dimension: | Micro(≤26mm) |

| Spherical: | Aligning Bearings |

| Accuracy Class: | P0, P6, P5, P4, P2 |

| Contact Angle: | 60° |

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Contribution of Sliding Bearings to Agricultural Machinery and Equipment

Sliding bearings play a crucial role in enhancing the functionality and efficiency of various agricultural machinery and equipment. Here’s how they contribute:

Smooth Movement: Sliding bearings provide smooth and low-friction movement in agricultural machinery, ensuring efficient operation of components like pivots, linkages, and joints.

Load Distribution: Sliding bearings distribute loads evenly across surfaces, reducing stress on components and extending the lifespan of agricultural equipment.

Durability: Sliding bearings are designed to withstand harsh conditions commonly encountered in agriculture, such as exposure to dirt, debris, and moisture.

Low Maintenance: Sliding bearings require minimal maintenance due to their self-lubricating properties, reducing downtime and operational costs.

Vibration Dampening: Sliding bearings help dampen vibrations in agricultural machinery, improving operator comfort and reducing wear on components.

Enhanced Precision: Sliding bearings ensure precise movement in equipment like planting and harvesting machinery, contributing to accurate and consistent operations.

Versatility: Sliding bearings are used in a wide range of agricultural applications, including tractors, combines, plows, irrigation systems, and more.

Cost Efficiency: Sliding bearings provide a cost-effective solution for agricultural machinery, offering long service life and reducing the need for frequent replacements.

Reliability: Sliding bearings offer reliable performance even in challenging agricultural environments, contributing to the overall reliability of the equipment.

Environmental Adaptability: Sliding bearings can handle varying weather conditions and exposure to agricultural chemicals without compromising performance.

Overall, sliding bearings play a vital role in ensuring the smooth operation, durability, and performance of agricultural machinery and equipment, contributing to increased productivity and reduced maintenance requirements in the agriculture sector.

Contribution of Sliding Bearings to Hydraulic Systems and Pumps

Sliding bearings play a crucial role in ensuring the smooth and efficient operation of hydraulic systems and pumps. Here’s how they contribute to these applications:

Load Distribution: Sliding bearings distribute the axial and radial loads generated by hydraulic components, such as pistons and impellers, across their surfaces. This helps prevent localized stress and ensures uniform load distribution, enhancing the overall stability of the system.

Reduced Friction: Sliding bearings minimize friction between moving parts within hydraulic systems and pumps. This friction reduction leads to lower energy consumption and less heat generation, contributing to improved efficiency and reduced wear and tear.

Fluid Film Formation: Properly lubricated sliding bearings create a fluid film between their surfaces. This fluid film serves as a barrier that prevents direct contact between the bearing surfaces, reducing friction and wear and enabling smooth movement even at high speeds.

Sealing Function: Sliding bearings often incorporate seals to prevent the ingress of contaminants, such as dirt and moisture, into the hydraulic system or pump. This sealing function helps maintain the integrity of the system’s components and extends their lifespan.

Alignment Compensation: In hydraulic systems, sliding bearings can compensate for minor misalignments between components, such as shafts and impellers. This ability to accommodate misalignment contributes to reduced stress and longer component life.

Quiet Operation: Sliding bearings help dampen vibrations and noise generated during the operation of hydraulic systems and pumps. This contributes to quieter and more comfortable working environments.

Customization: Sliding bearings can be designed and customized to meet the specific requirements of different hydraulic systems and pumps. This adaptability ensures optimal performance and longevity.

Overall, sliding bearings enhance the reliability, efficiency, and longevity of hydraulic systems and pumps by minimizing friction, distributing loads, facilitating smooth movement, and providing protection against contaminants. Their contribution is essential to achieving consistent and precise fluid transfer and power generation in various industrial applications.

Design Principles and Functions of Sliding Bearings

Sliding bearings, also known as plain bearings or journal bearings, operate on the principle of providing a low-friction interface between two moving surfaces. The design of sliding bearings is based on creating a film of lubrication between the bearing surface and the shaft or journal it supports. This film of lubrication separates the two surfaces and minimizes direct metal-to-metal contact, reducing friction and wear.

The main components and design principles of sliding bearings include:

- Bearing Material: Sliding bearings are typically made from materials with good wear resistance and self-lubricating properties, such as bronze, brass, or various polymers. These materials help reduce friction and prevent excessive wear.

- Lubrication: Lubrication is crucial for the proper functioning of sliding bearings. It can be provided by an external lubricant, solid lubricants embedded in the bearing material, or a combination of both. The lubrication forms a protective layer that reduces direct contact and minimizes friction.

- Clearance: Sliding bearings are designed with a specific clearance between the bearing and the shaft to accommodate the lubricating film and allow for proper movement. This clearance prevents seizing and binding of the bearing.

- Load Distribution: The design of sliding bearings ensures that the load is distributed over a larger surface area to prevent excessive stress on any single point. This feature is essential for handling heavy loads in industrial applications.

- Alignment and Misalignment: Sliding bearings can tolerate small misalignments between the bearing and the shaft. This flexibility allows them to accommodate minor shifts caused by thermal expansion, vibration, or other factors.

- Heat Dissipation: Sliding bearings can generate frictional heat during operation. Proper design includes features to facilitate heat dissipation and prevent overheating that could lead to premature wear.

- Application-Specific Design: The design of sliding bearings can vary based on the specific application requirements, including load capacity, speed, operating temperature, and environmental conditions.

The functions of sliding bearings include providing support to rotating or sliding shafts, reducing friction, absorbing and distributing loads, allowing for misalignment, and offering smooth movement even in dirty or contaminated environments. Sliding bearings are commonly used in various industrial machinery and equipment, including engines, pumps, conveyors, and manufacturing equipment.

Overall, the design principles and functions of sliding bearings make them suitable for applications where low friction, durability, load-bearing capacity, and adaptability to varying conditions are essential.

editor by CX 2024-03-24

China Good quality 693 Precision Miniature Ball Bearings for Motor Sliding Plates bearing and race

Product Description

|

Product Name |

693 2RS ZZ |

|

Product category |

Deep groove ball bearing |

|

Product material |

GR15 bearing steel |

|

Product advantage |

High speed low noise stable operation of High temperature resistance |

|

Application program |

Roller skates, motors, , spinning tops, automatic pumps, mixers,appliances |

|

Customer order protection |

Warranty for 1 year |

|

Minimum order quantity |

1 piece |

| Bearing model | Bore(mm) | O.D(mm) | Width (mm) | Chamfer | Load Rating(KN) | Maximumspeed(rpm) | Weight (Kg) | ||

| Dynamic | Static | Grease | Oil | ||||||

| 693 | 3 | 8 | 3 | 0.15 | 0.56 | 0.18 | 61000 | 68000 | 0.0006 |

| W693 | 3 | 8 | 4 | 0.15 | 0.56 | 0.18 | 61000 | 68000 | 0.0007 |

| 694 | 4 | 11 | 4 | 0.2 | 0.715 | 0.276 | 50000 | 56000 | 0.0018 |

| 695 | 5 | 13 | 4 | 0.2 | 1.08 | 0.43 | 44000 | 51000 | 0.0571 |

| 696 | 6 | 15 | 5 | 0.3 | 1.35 | 0.53 | 40000 | 46000 | 0.0038 |

| 697 | 7 | 17 | 5 | 0.3 | 1.61 | 0.715 | 37000 | 43000 | 0.0052 |

| 698 | 8 | 19 | 6 | 0.3 | 1.99 | 0.865 | 37000 | 42000 | 0.0073 |

| 699 | 9 | 20 | 6 | 0.3 | 2.48 | 1.09 | 34000 | 40000 | 0.0082 |

| 6900 | 10 | 22 | 6 | 0.3 | 2.7 | 1.27 | 32000 | 38000 | 0.009 |

| 6901 | 12 | 24 | 6 | 0.3 | 2.89 | 1.46 | 31000 | 36000 | 0.011 |

| 6902 | 15 | 28 | 7 | 0.3 | 4.36 | 2.24 | 27000 | 31000 | 0.016 |

| 6903 | 17 | 30 | 7 | 0.3 | 4.65 | 2.58 | 25000 | 29000 | 0.018 |

| 6904 | 20 | 37 | 9 | 0.3 | 6.37 | 3.68 | 20000 | 24000 | 0.036 |

| 6905 | 25 | 42 | 9 | 0.3 | 7.01 | 4.55 | 17000 | 21000 | 0.042 |

| 6906 | 30 | 47 | 9 | 0.3 | 7.24 | 5.01 | 16000 | 19000 | 0.048 |

| 6907 | 35 | 55 | 10 | 0.3 | 11.2 | 7.45 | 13000 | 17000 | 0.074 |

| 6908 | 40 | 62 | 12 | 0.3 | 14.6 | 10.2 | 11000 | 13000 | 0.11 |

| 6909 | 45 | 68 | 12 | 0.3 | 15.1 | 11.2 | 9800 | 12000 | 0.128 |

| 6910 | 50 | 72 | 12 | 0.3 | 15.6 | 12.2 | 9000 | 11000 | 0.132 |

Product Description

Products Application

Deep groove ball bearing is the most representative rolling bearing, simple structure, user, wide use. This kind of bearing is non-separable bearing, its inner and outer ring raceway are arc groove type, can bear radial load and two-way axial load; Low friction coefficient, high limit speed, suitable for high-speed rotation and low noise, low vibration occasions. This kind of bearing is widely used in automobile, machine tool, electric machine, instrument, construction machinery, railway rolling stock, agricultural machinery and various professional machinery.

Recommend Products

Company Profile

Our Advantages

Certifications

Customer praise

Packaging & Shipping

FAQ

1. Where is our factory? We are based in ZheJiang , China, We are an integrated enterprise of industry and trade start from 2008,sell to Domestic Market(40.00%),South America(10.00%),Eastern Europe(10.00%),North America(5.00%),Southeast Asia (5.00%), Africa(5.00%),Mid East(5.00%),Eastern Asia(5.00%) Central America(5.00%),Northern Europe(5.00%),South, Asia(5.00%). Our brand is DMC.

2. How can we guarantee quality?

Before we mass-produce the goods. Provide the customer with a free sample list, sample confirmation is satisfied with the

customer, we according to the requirements of the customer mass production if the bearing goods received by the customer are not

satisfied, the product can be returned and replaced within a month.

3.What do you get from us?

We can provide all kinds of bearings OEM&ODM customiz

-ed service.

You will get an excellent supplier and excellent bearing price. We will help you revitalize your career and try our best to let

customers earn more money.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Non-Aligning Bearing |

|---|---|

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Cage: | Steel Cage.Brass Cage.Nylon Cage |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Differences Between Plain Sliding Bearings and Self-Lubricating Bearings

Plain sliding bearings and self-lubricating bearings are two distinct types of bearings used in various applications. Here are the key differences between them:

Plain Sliding Bearings:

- Plain sliding bearings, also known as bushings, are simple bearing components that consist of a cylindrical sleeve made of a bearing material.

- These bearings require external lubrication, such as grease or oil, to reduce friction and wear between the bearing and the shaft.

- Regular maintenance and lubrication are essential to ensure proper operation and longevity.

- Plain sliding bearings are cost-effective and suitable for applications where lubrication can be easily provided.