Product Description

Product Parameters

| Product Name | Deep Groove Ball Bearings | |

| Brand Name | NMN | |

| Material | Chrome Steel GCr15 Stainless Steel Ceramic Nylon | |

| Cage | Steel Brass Nylon | |

| Weight(Kg) | 0.0048 | |

| Clearance | C0 C2 C3 C4 C5 | |

| Seals Type | Open Z 2Z 2RS Znr 2RS1 2rsh 2rsl 2znr | |

| Precision Grade | P0 P6 P5 P4 P2 | |

| Vibration | V1 V2 V3 V4 | |

| Quality | ABEC1, 3, 5, 7,9 | |

| Load Rating(kN) | Cr | 1.76 |

| Cor | 0.68 | |

| Limiting Speed | Grease | 40000 |

| Oil | 32000 | |

| Serice | OEM ODM | |

| Sample | Available | |

| Port | HangZhou/ZheJiang | |

Product Details

Single row deep groove ball bearings are used in a wide variety of applications, they are simple in design, non-separable, suitable for high speeds and are robust in operation, and need little maintenance. Deep raceway grooves and the close conformity between the raceway grooves and the balls enable deep groove ball bearings to accommodate axial loads in both directions, in addition to radial loads.

625 bearing has the advantages of low noise, low friction and high speed, and is equipped with sealing cover, grease, etc., to extend the life of the product.

We provide OEM, ODM and other services, and provide you with relevant consulting information to help you with bearing selection, clearance configuration, product life and reliability analysis. We offer localized shipping solutions to save your shipping costs.

We can provide free samples, can accept custom LOGO or drawings, can design packaging according to requirements.

Bearing Models

| Number | Specifiction | Load Rating (KN) | Limiting Speed (r/min) | Weight(Kg/pc) | |||||

| d(mm) | D(mm) | B(mm) | r(mm) | Cr | Cor | Grease | Oil | ||

| 604 | 4 | 12 | 4 | 0.2 | 0.9 | 0.36 | 43000 | 51000 | 0.002 |

| 605 | 5 | 14 | 5 | 0.2 | 1.33 | 0.505 | 39000 | 46000 | 0.0035 |

| 606 | 6 | 17 | 6 | 0.3 | 2.19 | 0.865 | 30000 | 38000 | 0.006 |

| 607 | 7 | 19 | 6 | 0.3 | 2.24 | 0.91 | 28000 | 3600 | 0.008 |

| 608 | 8 | 22 | 7 | 0.3 | 3.35 | 1.4 | 26000 | 34000 | 0.012 |

| 609 | 9 | 24 | 7 | 0.3 | 3.4 | 1.45 | 22000 | 30000 | 0.014 |

| 6000 | 10 | 26 | 8 | 0.3 | 4.55 | 1.96 | 20000 | 28000 | 0.019 |

| 6001 | 1 | 28 | 8 | 0.3 | 5.1 | 2.39 | 19000 | 26000 | 0.571 |

| 6002 | 15 | 32 | 9 | 0.3 | 5.6 | 2.84 | 18000 | 24000 | 0.03 |

| 6003 | 17 | 35 | 10 | 0.3 | 6.8 | 3.35 | 17000 | 22000 | 0.039 |

| 6004 | 20 | 42 | 12 | 0.6 | 9. | 5.05 | 1000 | 19000 | 0.069 |

| 6005 | 25 | 47 | 12 | 0.6 | 10.1 | 5.85 | 13000 | 17000 | 0.08 |

| 6006 | 30 | 55 | 13 | 1.0 | 13.2 | 8.3 | 12000 | 15000 | 0.116 |

| 6007 | 35 | 62 | 14 | 1.0 | 16 | 10.3 | 10000 | 13000 | 0.155 |

| 6008 | 40 | 8 | 15 | 1.0 | 16.8 | 11.5 | 8000 | 11000 | 0.185 |

| 6009 | 45 | 5 | 16 | 1.0 | 21 | 15.1 | 7200 | 9000 | 0.231 |

| 6571 | 50 | 80 | 16 | 1.0 | 21.8 | 16.6 | 6400 | 7800 | 0.25 |

| 6011 | 55 | 90 | 18 | 1.1 | 28.3 | 21.2 | 5700 | 7000 | 0.362 |

| 6012 | 60 | 95 | 18 | 1.1 | 29.5 | 23.2 | 5000 | 6300 | 0.385 |

| 6013 | 65 | 100 | 18 | 1.1 | 31.9 | 25 | 4800 | 6100 | 0.44 |

| 6014 | 70 | 110 | 20 | 1.1 | 39.7 | 31 | 4600 | 5800 | 0.6 |

| 6015 | 75 | 115 | 20 | 1.1 | 41.6 | 33.5 | 4400 | 5600 | 0.64 |

| 6016 | 80 | 125 | 22 | 1.1 | 47.5 | 40 | 4300 | 5500 | 0.854 |

| 6017 | 85 | 130 | 22 | 1.1 | 49.5 | 43 | 200 | 5300 | 0.89 |

| 6018 | 90 | 140 | 24 | 1.5 | 58 | 49.5 | 4000 | 5100 | 1.02 |

| 624 | 4 | 13 | 5 | 0.2 | 1.31 | 0.49 | 36000 | 45000 | 0.0032 |

| 625 | 5 | 16 | 5 | 0.3 | 1.76 | 0.68 | 32000 | 40000 | 0.0048 |

| 626 | 6 | 19 | 6 | 0.3 | 2.34 | 0.885 | 28000 | 36000 | 0.0081 |

| 627 | 7 | 22 | 7 | 0.3 | 3.35 | 1.40 | 26000 | 34000 | 0.013 |

| 628 | 8 | 24 | 8 | 0.3 | 4.00 | 1.59 | 24000 | 32000 | 0.017 |

| 629 | 9 | 26 | 8 | 0.3 | 4.55 | 1.96 | 22000 | 40000 | 0.0048 |

Packaging & Shipping

·Plastic rolling packing + Plastic bag + Paper carton

·Single Box + Plastic rolling packing + Plastic bag + Paper carton+pallet

·According to customer requirement

Applications

About Us

ZheJiang CZPT Bearing Group is a professional bearing manufacturer and exporter in China. We have been engaged in bearing industry for 20 years. Our company is specialized in producing Deep Groove Ball Bearings, Tapered Roller Bearings, Spherical Roller Bearings and Special Bearings in accordance with Customers’ designs.Our bearings has been widely applied into agricultural equipments, home appliances, power equipments, machine tools, automotives and engineering machinery, etc.

Our production is strictly executed with ISO9001 and ISO14001. Our products are mainly exported to Singapore, South Kora, Vietnam, Thailand, Turkey, Pakistan, Australia, Polan, France, UK, South America, USA, South Africa and other countries and regions of the world, with great public praise of high quality and reasonable price.

Company Profile

FAQ

1.Q:Could you supply free sample of bearing for our test?

A:Yes. Please afford the express fee and we will send you the sample within your first order.

2.Q:Sample time?

A:Within 3-4 days.

3.Q:Are you a factory or a Trade Company for Bearing ?

A:We are the factory.

4.Q:Whether you could make your products by our color?

A:Yes, The color of products can be customized if you can meet our MOQ.

5.Q:Could you accept OEM and customize?

A:Yes, OEM and ODM are accepted and we can customize for you according to sample or drawing.

6.Q:Do you have stocks?

A:Yes, most of the bearings showing on alibaba are in stock,especialy big bearings.

We sincerely hope we can build a long term relationship with all the clients and we also have great confidence in cooperating with every potential customer by most premium service and competitive price.

Welcome your inquiry and welcome your visit.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | Nmn |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Samples: |

US$ 0.01/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Improvement of Heavy Machinery Operation with Sliding Bearings

Sliding bearings play a crucial role in enhancing the operation of heavy machinery, such as mining equipment. Here’s how they contribute:

Reduced Friction and Wear:

Sliding bearings are designed to minimize friction between moving parts. In heavy machinery, where components are subjected to substantial loads and harsh conditions, reducing friction is essential to prevent premature wear and damage. Sliding bearings help distribute loads evenly and provide a smooth surface for components to slide against, reducing the risk of friction-induced failures.

Increased Durability:

The robust construction and materials used in sliding bearings make them well-suited for heavy machinery applications. They can withstand the heavy loads, impacts, and vibrations commonly encountered in mining equipment. Their durability contributes to the overall reliability and longevity of the machinery.

Improved Efficiency:

Efficiency is critical in heavy machinery to maximize productivity while minimizing energy consumption. Sliding bearings contribute to improved efficiency by reducing energy losses due to friction. With lower friction, machinery components can move more freely, requiring less energy to overcome resistance.

Resistance to Contaminants:

Mining environments are often filled with dust, dirt, and debris that can infiltrate machinery components. Sliding bearings are designed to operate effectively even in contaminated conditions. Their design and materials help prevent the intrusion of contaminants, reducing the risk of premature wear and component failure.

Enhanced Load Distribution:

Heavy machinery, especially in mining, experiences dynamic and uneven loads. Sliding bearings help distribute these loads evenly across surfaces, preventing localized stress concentrations. This load distribution contributes to the machinery’s overall structural integrity and minimizes the risk of catastrophic failures.

In conclusion, sliding bearings are integral to the efficient and reliable operation of heavy machinery in industries like mining. Their ability to reduce friction, enhance durability, improve efficiency, resist contaminants, and distribute loads makes them invaluable components for ensuring the smooth functioning of mining equipment.

Benefits of Sliding Bearings in Low-Speed and Heavy-Load Applications

Sliding bearings offer significant advantages in low-speed and heavy-load applications, where their unique characteristics provide optimal performance. Some examples of scenarios where sliding bearings benefit such applications include:

- Mining Equipment: Sliding bearings are used in mining machinery such as crushers, mills, and conveyor systems. These applications often involve heavy loads and low speeds, where sliding bearings can provide robust support and reliable operation.

- Steel Mills: In steel production, sliding bearings are utilized in rolling mills and continuous casting machines. These operations require handling heavy loads and slow rotation speeds, making sliding bearings suitable for providing the necessary support.

- Hydraulic Systems: Sliding bearings are used in hydraulic cylinders, where slow and controlled movements are required for applications like construction machinery, material handling equipment, and heavy-duty presses.

- Cranes and Lifts: Sliding bearings are employed in the construction of cranes, elevators, and lifting platforms. These applications involve lifting and lowering heavy loads at controlled speeds, making sliding bearings crucial for smooth and reliable motion.

- Wind Turbines: Sliding bearings are used in the yaw and pitch systems of wind turbines. These systems need to handle the substantial weight of the turbine blades and operate at low speeds to optimize energy generation.

In these scenarios and more, sliding bearings provide the necessary support, stability, and durability required for low-speed and heavy-load applications.

Advantages of Sliding Bearings Compared to Other Bearings

Sliding bearings, also known as plain bearings or journal bearings, offer several advantages compared to other types of bearings. These advantages make them suitable for specific applications where their characteristics are beneficial:

- High Load-Carrying Capacity: Sliding bearings can handle high loads due to their larger contact area and distribution of pressure, making them suitable for heavy machinery and industrial equipment.

- Low Friction: Sliding bearings operate on the principle of sliding friction, which can result in lower frictional losses and energy consumption compared to rolling element bearings.

- Simplicity: Sliding bearings have a straightforward design with fewer components, reducing complexity and potential points of failure.

- Cost-Effectiveness: The simpler design and manufacturing process of sliding bearings can lead to lower production costs and maintenance expenses.

- Shock and Vibration Absorption: Sliding bearings can dampen shocks and vibrations due to their ability to accommodate misalignments and absorb dynamic forces.

- High-Temperature Applications: Some sliding bearings are capable of operating in high-temperature environments where other types of bearings might fail.

- Self-Lubrication: Some sliding bearings are designed with self-lubricating materials, reducing the need for external lubrication and maintenance.

- Noisiness: Sliding bearings often produce less noise than rolling element bearings, which can be advantageous in noise-sensitive applications.

- Corrosion Resistance: Sliding bearings made from materials such as bronze or plastic can offer better corrosion resistance in certain environments.

- Adaptability to Dirty Environments: Sliding bearings can perform well in dirty or contaminated environments where rolling element bearings might be more prone to failure due to debris.

However, it’s important to note that sliding bearings also have limitations, such as higher frictional heat generation, potential for stick-slip behavior, and limited suitability for high-speed applications. The choice between sliding bearings and other types of bearings depends on the specific requirements of the application and the trade-offs that need to be considered.

editor by CX 2024-05-09

China Hot selling High Performance U Grooved Track Roller Wheel Bearings for Sliding Door and Window Lfr50/5-6kdd Lfr50/5-6npp 5mmx17mmx8mm with Best Sales

Product Description

Product Description

Deep Groove Ball Bearing

Manufacturers: Radial ball bearings are CZPT to accommodate low to heavy radial loads and low to moderate thrust loads in either direction. Radial Deep Groove Ball Bearings are available with metal shields (ZZ) or rubber seals (2RS). Several tolerance grades (Abec 1-9), internal clearance (C2 to C4) and cage designs are available to best suit the running precision and speed of the application.

Common Options of Radial Deep Groove Ball Bearings:

- ZZ– Two Metal Shields

- 2RS– Two Rubber Seals

- NR– Snap Ring

- M– Brass Cage

- C0– Normal Internal Clearance

- C3– Greater than normal

Single row deep groove ball bearings are used in a wide variety of applications, they are simple in design, non-separable, suitable for high speeds and are robust in operation, and need little maintenance. Deep raceway grooves and the close conformity between the raceway grooves and the balls enable deep groove ball bearings to accommodate axial loads in both directions, in addition to radial loads.

Single row deep groove ball bearings are manufactured as open type (unsealed), sealed and shielded, the most popular sizes of deep groove ball bearings are also produced in sealed versions with shields or contact seals on 1 or both sides, the bearings with shields or seals on both sides are lubricated for life and are maintenance free. A sealed bearings seals has contact on the bearings inner and outer, a shielded bearings shield has contact on the outer only, and Shielded bearings are primarily intended for applications where the inner ring rotates. If the outer ring rotates, there is a risk that the grease will leak from the bearing at high speeds.

Bearing Data – General

RSH or RS = Sheet steel reinforced contact seal of acrylonitrile-butadiene rubber (NBR) on 1 side of the bearing

2RSH or 2RS = RSH or RS contact seal on both sides of the bearing

RSL = Sheet steel reinforced low-friction contact seal of acrylonitrile-butadiene rubber (NBR) on 1 side of the bearing

2RSL = RSL low friction contact seal on both sides of the bearing

Z = Shield of pressed sheet steel on 1 side of the bearing

2Z or ZZ = Z-Shield on both sides of the bearing

About this item

- Size: 6200-2RS (Inner Dia.=10mm, Outer Dia.=30mm, Thickness=9mm)

- Sealed on BOTH SIDES of the bearing to keep lubricant in. Suitable for complex environment

- Made from Carbon Steel, durability and resistance to under heavy loads

- ABEC Tolerance 1 (P0), Z1 Noise Level for most general use

- Pre-Lubricated, Easy to maintain

Product Specifications

| Bearing Type | Ball Bearing |

|---|---|

| Compatible Lubricant Type | Oil |

| Item Thickness | 9 millimeters millimeters |

| Material | Carbon Steel |

| Measurement System | Metric |

| Size | 10mmx30mmx9mm |

Company Profile

ZheJiang CZPT Bearing Co., Ltd. is affiliated to ZheJiang Kaidi Bearing Group – a specialized manufacturer of kinds of bearings for about 20 years.

Our company is specialized in producing Deep Groove Ball Bearings, Tapered Roller Bearings, Spherical Roller Bearings and Special Bearings in accordance with Customers’ designs.Our bearings has been widely applied into agricultural equipments, home appliances, power equipments, machine tools, automotives and engineering machinery, etc.

Our Products

ZheJiang CZPT Bearing Co., Ltd. is a specialized manufacturer of ball bearings for about 20 years. Our main products include:

1, Miniature Bearings: like 608, 609, 625, 626, 693, 695, etc;

2, Deep Groove Ball Bearings: like 6000, 6200, 6300, 6800, 6900, 16000 Series;

3,Non-Standard Bearings: U grooved bearings, V grooved bearings, double grooved bearings, bearing rollers with or without plastic injection. 4,Pillow Block Bearing: UCP/ UCF/ UCFL;

5,Tapered Roller Bearings

6,Linear Motion Bearings

Processing Process

we have manufacture bearing more than 20 years, and can produce different style of bearings. Our factory starts production from raw materials. We have a 20-person R&D team and launch a new product every 5 days. We have more than 600 people to produce bearing team, we produce products, the price is the most competitive in China.

Packaging & Shipping

Our Activities

FAQ

|

1.Q:Do you know the Detail Size for the Bearing ? 2.Q: This Size of Bearing is common parts? 3.Q:Are you a factory or a Trade Company for Bearing ? 4.Q:How many the MOQ of the Bearing? 5.Q:Could you supply free sample of bearing for our test? 6.Q:Could you accept OEM and customize? 7.Q:Do you have stocks? |

Contact Us

Jane

ZheJiang CZPT Bearing Co., Ltd.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 15° |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Thrust Bearing |

| Material: | Bearing Steel |

| Samples: |

US$ 0.05/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Considerations for Selecting Appropriate Sliding Bearings

Choosing the right type and size of sliding bearing is crucial for ensuring optimal performance and longevity in various applications. Here are key considerations to keep in mind:

Load and Application: Determine the specific load and application requirements. Different sliding bearings are designed to handle varying loads, speeds, and operating conditions. Consider whether the bearing will experience radial, axial, or combined loads, as well as the expected range of motion.

Material Compatibility: Select materials that are compatible with the operating environment. Consider factors such as corrosion resistance, temperature tolerance, and exposure to chemicals or contaminants. Common bearing materials include bronze, steel, and self-lubricating polymers.

Lubrication: Proper lubrication is essential for reducing friction and wear in sliding bearings. Choose a lubrication method that suits the application, whether it’s grease, oil, or self-lubricating materials. Some sliding bearings are designed for maintenance-free operation.

Design and Configuration: Determine the appropriate bearing design, such as bushings, thrust washers, or linear guides. Consider the bearing’s dimensions, including inner and outer diameter, length, and width. The bearing’s configuration should match the available space and mounting requirements.

Load Distribution: Ensure that the selected sliding bearing can evenly distribute the applied load across its surface. This helps prevent premature wear and ensures the bearing’s longevity. Consider the bearing’s load capacity and how it aligns with the actual load demands.

Friction and Wear: Evaluate the bearing’s coefficient of friction and wear characteristics. Lower friction and wear rates contribute to longer bearing life and improved efficiency. Consider whether the bearing requires initial running-in to reach optimal performance.

Maintenance and Service Life: Consider the maintenance requirements and expected service life of the sliding bearing. Some applications may benefit from bearings with extended maintenance intervals or self-lubricating properties, while others may prioritize easy replacement.

Cost-Efficiency: Balancing performance with cost is essential. While high-performance materials and features can enhance bearing performance, they may also increase the upfront cost. Choose a solution that aligns with your budget and long-term operational goals.

Environmental Conditions: Factor in the environmental conditions the bearing will operate in. For example, marine environments may require bearings with exceptional corrosion resistance, while high-temperature applications demand materials with thermal stability.

Supplier Expertise: Partner with reputable suppliers who offer technical expertise and a range of sliding bearing solutions. Suppliers with a strong track record can provide guidance in selecting the most suitable bearing for your specific application.

By carefully considering these factors, you can confidently choose the appropriate type and size of sliding bearing that meets your application’s requirements and ensures optimal performance and reliability.

Maintenance Practices to Extend the Lifespan of Sliding Bearings

Proper maintenance is essential for maximizing the lifespan of sliding bearings and ensuring optimal performance. Here are specific practices that can help extend the life of sliding bearings:

Regular Lubrication: Adequate lubrication is crucial for minimizing friction and wear between sliding surfaces. Follow manufacturer recommendations for lubrication intervals and use the appropriate lubricants for the operating conditions.

Clean Environment: Keep the surrounding environment clean and free from dust, dirt, and contaminants. Regularly clean the machinery or equipment to prevent debris from entering the bearing area.

Seal Integrity: Ensure that bearing seals are in good condition to prevent contaminants from entering and lubricant from escaping. Replace damaged seals promptly to maintain proper protection.

Alignment and Mounting: Proper alignment and mounting of sliding bearings are critical to distribute loads evenly and prevent excessive wear. Follow manufacturer guidelines for installation procedures and torque specifications.

Regular Inspections: Schedule routine inspections to detect early signs of wear, damage, or misalignment. Visual inspections, temperature checks, and vibration analysis can help identify issues before they escalate.

Maintenance Records: Maintain detailed records of maintenance activities, including lubrication schedules, inspections, and replacements. This information can help track the condition of sliding bearings and plan maintenance tasks effectively.

Temperature Management: Control operating temperatures within recommended limits. Excessive heat can degrade lubricants and accelerate wear, while extreme cold can affect bearing performance.

Load Management: Avoid subjecting sliding bearings to loads beyond their specified capacities. Overloading can lead to premature wear and damage.

Training and Education: Ensure that personnel responsible for maintenance are adequately trained in proper procedures. Knowledgeable staff can perform maintenance tasks accurately and identify potential issues.

Timely Replacement: When wear or damage is detected that exceeds acceptable limits, replace sliding bearings promptly to prevent further damage to the machinery or equipment.

By implementing these maintenance practices, you can significantly extend the lifespan of sliding bearings, reduce downtime, and optimize the performance of machinery and equipment.

Impact of Proper Lubrication on Sliding Bearings

Proper lubrication plays a critical role in the performance and longevity of sliding bearings. Here’s how it affects their operation:

- Reduced Friction and Wear: Lubrication forms a thin film between the sliding surfaces of the bearing, reducing direct metal-to-metal contact. This minimizes friction and wear, which can significantly extend the bearing’s lifespan.

- Heat Dissipation: Lubricants help dissipate heat generated during operation by carrying away excess heat from the friction zones. This prevents overheating and potential damage to the bearing and surrounding components.

- Corrosion Prevention: Lubricants provide a protective barrier against moisture and corrosive substances, preventing the formation of rust and corrosion on the bearing surfaces.

- Sealing Effect: Proper lubrication can help create a sealing effect that prevents contaminants from entering the bearing, maintaining a clean and efficient operating environment.

- Noise and Vibration Reduction: Adequate lubrication helps dampen noise and reduce vibration caused by friction between bearing surfaces. This contributes to quieter and smoother operation.

- Enhanced Load Distribution: Lubrication ensures even load distribution across the bearing surfaces, preventing localized wear and extending the bearing’s overall life.

- Stability and Performance: Proper lubrication maintains consistent performance and stability by minimizing variations in friction and reducing the risk of sudden failures.

- Seizure Prevention: Lubricants prevent sliding surfaces from seizing or sticking together, even during periods of prolonged inactivity.

- Optimized Efficiency: Well-lubricated bearings experience less energy loss due to friction, resulting in improved overall efficiency of the machinery.

Choosing the right lubricant type, viscosity, and lubrication interval is crucial to ensuring the optimal performance and durability of sliding bearings. Regular maintenance and monitoring of lubrication levels are essential to prevent issues and extend the bearing’s service life.

editor by CX 2024-05-08

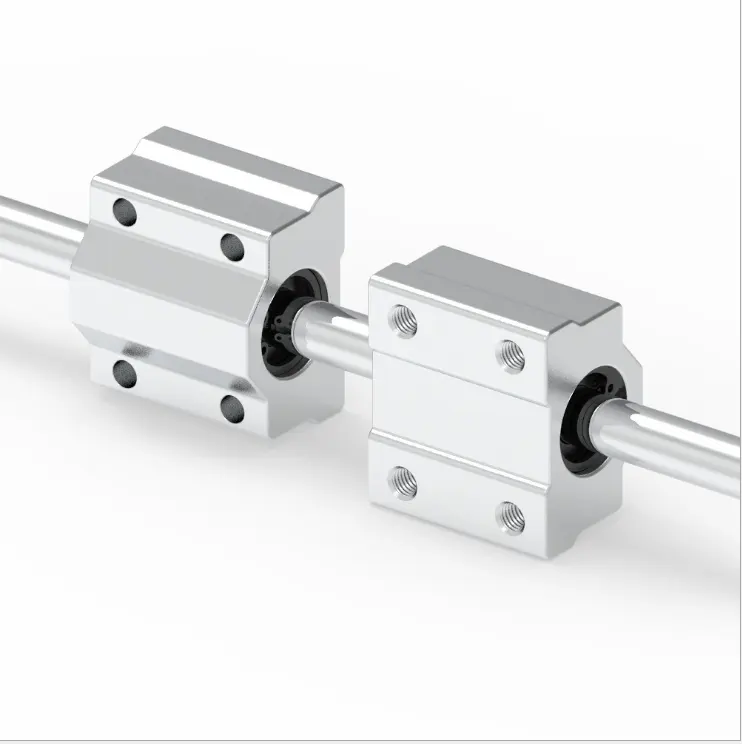

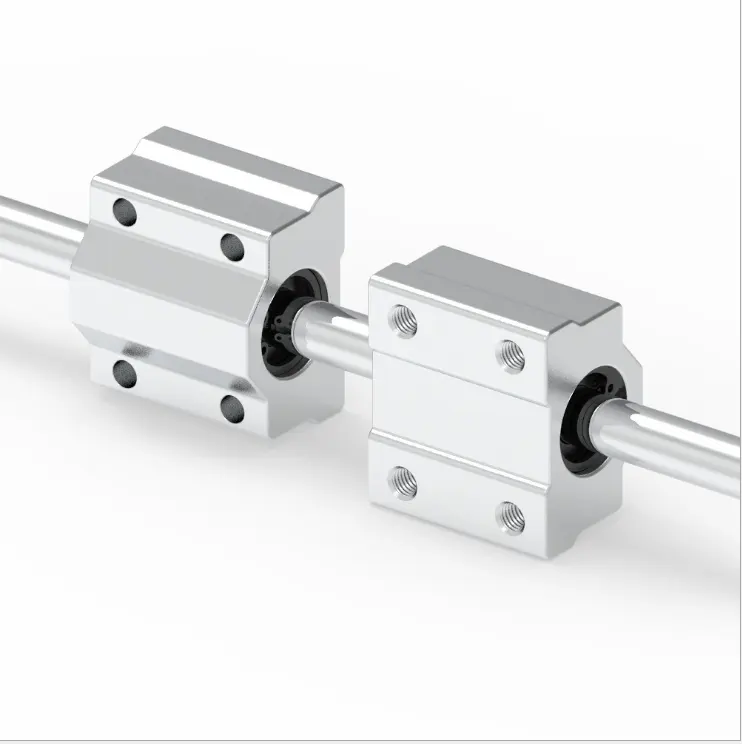

China Best Sales Linear Sliding Unit Lm6uu Linear Ball Bearings for CNC Machine 3D Printer ball bearing

Product Description

Product Description

- Bearing structure: consists of outer cylinder, retainer, balls, side seals;

- Premium grade raw material: GCr15 bearing steel cylinder, G10 class precision ball, PA66 plastic retainer;

- Cylinder metal body is heat treated and hardened to enhance to the rigidity and working life;

- Both the inner bore and outer cylinder surface are ground several procedures to guarantee the precision;

- Completely washed by the super sonic washing machine, pre-lubricated;

- Main features: high precision and rigidity, low friction, ease of assembly and replacement, good interchangeability;

- Good quality at affordable rates, price is very economic and nice;

- Ideal transmission component for linear motion movement, widely used in CNC machines, factory automation, industrial machines, electric tools, textile machines, fitting equipment, etc.;

- Wide size range for option, models including(special size has to be customized):

LM3, LM4, LM5UU, LM6UU, LM8SUU, LM8UU, LM10UU, LM12UU, LM13UU, LM16UU, LM20UU, LM25UU, LM30UU, LM35UU, LM40UU, LM50UU, LM60UU, LM80UU, LM100UU, LM120UU, LM150UU, etc.

Product Parameters

Detailed Photos

Certifications

Packaging & Shipping

1.According to the quantity and the ship method of your order, we will choose the best packing ways.

2.For example, if the products shipped by TNT,DHL,FedEx, the goods would be packed by paper carton for economic delivery. As bulk order shipped by sea, the goods would be packed by wooden carton.

Our Advantages

FAQ

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Q1:Who we are?

We are the factory based in ZHangZhoug,China,start from 2007 sell to all over the.world.the factory area is around 45000 square meters.we have 900 employees.

Q2: Do you have a catalogue?

Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q3: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q4 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.

Q5: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the

shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

Recommend product

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Magnetically, Corrosion Resistant, High Speed, High Precision |

|---|---|

| Function: | Super |

| Flange Shape: | Oval |

| Shape: | Flange |

| Series: | LM |

| Material: | Bearing Steel |

| Samples: |

US$ 16.8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Differences Between Plain Sliding Bearings and Self-Lubricating Bearings

Plain sliding bearings and self-lubricating bearings are two distinct types of bearings used in various applications. Here are the key differences between them:

Plain Sliding Bearings:

- Plain sliding bearings, also known as bushings, are simple bearing components that consist of a cylindrical sleeve made of a bearing material.

- These bearings require external lubrication, such as grease or oil, to reduce friction and wear between the bearing and the shaft.

- Regular maintenance and lubrication are essential to ensure proper operation and longevity.

- Plain sliding bearings are cost-effective and suitable for applications where lubrication can be easily provided.

- They are commonly used in low-speed and low-load applications, where the shaft slides within the bearing.

Self-Lubricating Bearings:

- Self-lubricating bearings, also known as maintenance-free bearings, are designed to operate without the need for external lubrication.

- These bearings incorporate solid lubricants, such as graphite, PTFE (polytetrafluoroethylene), or other additives, directly into the bearing material.

- The solid lubricants are released gradually as the bearing operates, reducing friction and providing a consistent lubricating film.

- Self-lubricating bearings are ideal for applications where frequent maintenance or lubrication is impractical or not feasible.

- They are suitable for both low-load and high-load applications, as the self-lubricating properties help extend the bearing’s service life.

In summary, plain sliding bearings require external lubrication and are suitable for applications where lubrication can be provided, while self-lubricating bearings incorporate solid lubricants and operate without the need for regular maintenance. The choice between these two types depends on factors such as the application’s operating conditions, maintenance requirements, and budget considerations.

Impact of Materials on Sliding Bearing Performance and Durability

The choice of materials used in sliding bearings significantly influences their performance, longevity, and suitability for specific applications. Different materials offer varying characteristics that affect factors such as friction, wear resistance, load capacity, and corrosion resistance. Here are some common materials and their effects:

- Bronze Bearings: Bronze bearings, often made from bronze alloys, offer good load-carrying capacity and resistance to wear. They are suitable for applications with moderate to heavy loads and low to moderate speeds. Bronze bearings also have good heat dissipation properties.

- Steel Bearings: Steel bearings, particularly those made from stainless steel, provide excellent corrosion resistance and are suitable for applications exposed to harsh environments or moisture. Steel bearings are often used in marine and food processing industries.

- Polymer Bearings: Polymer bearings, such as those made from materials like PTFE (polytetrafluoroethylene) or nylon, offer low friction and self-lubricating properties. They are suitable for applications where minimizing friction and wear is critical.

- Composite Bearings: Composite bearings combine different materials to achieve specific performance characteristics. For instance, they might feature a polymer matrix with embedded reinforcing fibers for improved load capacity and wear resistance.

- Graphite Bearings: Bearings with graphite as a lubricating element can operate without additional lubrication in certain conditions, reducing maintenance needs and offering self-lubricating properties.

The selection of materials should consider factors such as the application’s operating conditions, load requirements, speed, temperature, and the presence of corrosive substances. The right material choice ensures optimal performance, durability, and minimal maintenance for sliding bearings.

Common Applications and Industries of Sliding Bearings

Sliding bearings are utilized across a wide range of applications and industries due to their unique advantages. Some common applications and industries where sliding bearings are commonly used include:

- Automotive Industry: Sliding bearings are found in engines, transmissions, suspension systems, and various automotive components.

- Industrial Machinery: They are used in manufacturing equipment, conveyors, printing machines, and more.

- Power Generation: Sliding bearings are crucial in turbines, generators, and power transmission systems.

- Aerospace: They play a role in aircraft landing gear, control systems, and propulsion mechanisms.

- Marine: Sliding bearings are used in ship engines, propellers, and steering systems.

- Construction and Mining: They are found in heavy machinery, excavators, loaders, and construction equipment.

- Oil and Gas: Sliding bearings are used in drilling rigs, pumps, compressors, and refineries.

- Railway: They are employed in locomotives, train wheels, and rail systems.

- Medical Equipment: Sliding bearings are used in medical devices, imaging equipment, and surgical instruments.

- Textile Industry: They play a role in weaving machines, spinning frames, and looms.

- Food and Beverage: Sliding bearings are utilized in food processing equipment and packaging machinery.

- Renewable Energy: They are used in wind turbines, solar tracking systems, and other renewable energy applications.

Sliding bearings provide reliable support and smooth motion in various environments, making them essential components in a wide range of industries.

editor by CX 2024-03-30

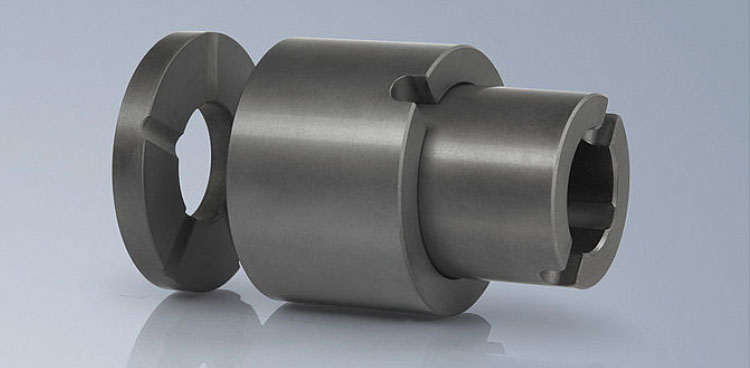

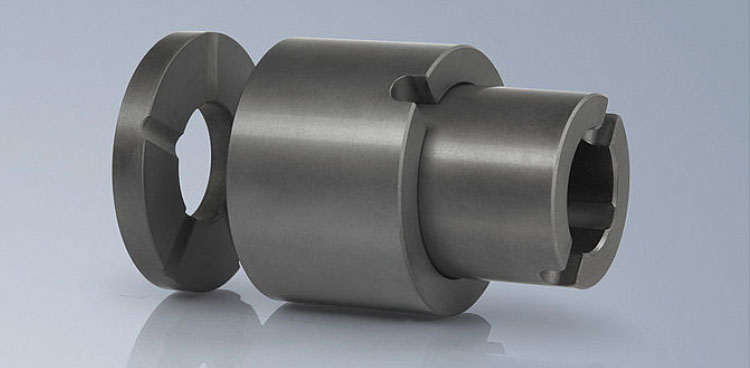

China Best Sales Manufacture of Lightweight Graphite Sliding Bearings for Textiles Machines manufacturer

Product Description

manufacture of lightweight Graphite sliding Bearings for textiles machines

lttrade

A: company profile

Our facility is the biggest producer of graphite molds in North of China, which has over 15 years of experiences on graphite mold design and producing. With the reliable factory technical support and good after-sales service, our graphite molds have covered all china market. Now, combined with export experiences of L.T TRADE, Our products will be more complete and go further. Our major products now are: graphite plate, graphite crucible, graphite ring, graphite wire saw, graphite hot cutting pieces, graphite sintering CZPT segment etc. And very welcome you provide drawings and designs, we can provide OEM and ODM.

B: Why choose us

Graphite CZPT plays a dual role in the process of manufacture: Heating element and Supporting mold. The quality of graphite mold is very important, will directly affect the next CZPT tools’ accuracy and appearance. So, which kind of graphite mold is suitable for sintering CZPT tools:

- Good performance on conductivity and high rate resistivity

- Enough Mechanical Strength

- Good performance on Oxidation resistance

- Durable

Why choose us:

Raw materials is very important, We only use Ultrafine particle structure, High purity and High graphitization raw graphite materials.

Our finished graphite mold is:

- dense structure and low porosity

- Fined surface and low rate heat-deformation

- High mechanical strength and machining accuracy

- Oxidation resistance and durable

C: Product features

1. The processing materials are ultrafine granule structure, high purity and graphite with high graphitization degree.

2. High hardness, good anti-oxidation performance and high machining accuracy

3. Good conductivity, high resistivity, sufficient mechanical strength

4. Small porosity and dense structure.

5. Excellent thermal shock resistance, conductive and thermal conductivity.

6. High temperature resistance, corrosion resistance, acid and alkali resistance, good wear resistance.

7. Surface can be treated with anti-oxidation.

D: Processing method

1. Customer provide design drawings.

2. Our technical team will check, analyze the drawings, and divide the drawing to reasonable parts if needed, and prepare proper graphite blocks . Our mechanics will design and customize grinding wheel.

3. Our workers will grinding and polishing graphite block according to the instructions of mechanics. This process may need operating few times if needed. We will strictly keep deviation within ±0.03-0.08mm.

4. Then our packing team will assembling different parts into a whole graphite mold. During the assembling period, unqualified products will be picked out.

E: Attribute table

| Density g/cm³ | 1.75-1.9 |

| Resistivity μΩ·m | ≤18 |

| Compressive strength Mpa | 40-80 |

| Porosity % | ≤26 |

| Elasticity Modulus Gpa | 6-18 |

| Thermal expansion coefficient 10-6/ºC | 1.47-4.25 |

| Ash content % | ≤0.5 |

| Temperature resistance ºC | 4350 |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Graphite Mold |

|---|---|

| Composition: | 99.9% High Purity Graphite |

| Carbon Content: | High-Carbon |

| Grade: | High Purity Graphite |

| Forming Way: | Molded Graphite |

| Crystal Morphology: | Compact Crystalline Graphite |

| Samples: |

US$ 0.30/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Advancements in Sliding Bearing Technology

Recent years have witnessed significant advancements in sliding bearing technology, leading to improved performance, durability, and efficiency in various applications. Some notable developments include:

Self-Lubricating Materials: The use of advanced self-lubricating materials, such as composite polymers and solid lubricants, has reduced the need for external lubrication, enhancing maintenance-free operation.

Nano-Coatings: Nano-coatings with improved wear resistance and reduced friction have been applied to sliding bearings, extending their lifespan and optimizing performance in demanding environments.

Improved Friction Management: Advanced surface texturing and micro-grooving techniques have been employed to manage friction and reduce wear, contributing to smoother operation and increased efficiency.

Bearing Monitoring Systems: Integration of sensors and monitoring systems allows real-time tracking of bearing health, enabling predictive maintenance and reducing unexpected downtime.

Customization: Modern manufacturing techniques, such as 3D printing and precision machining, allow for customized sliding bearings tailored to specific applications, improving overall system performance.

Environmentally Friendly Solutions: Development of environmentally friendly lubricants and materials ensures compliance with regulations and minimizes the impact of sliding bearing technology on the environment.

High-Load Capacities: Advances in material science and engineering have led to sliding bearings with increased load-carrying capacities, making them suitable for heavy-duty applications.

Enhanced Wear Resistance: Improved material compositions and surface treatments have enhanced wear resistance, reducing the need for frequent replacements and maintenance.

Reduced Noise and Vibration: Innovations in design and materials have resulted in sliding bearings that produce less noise and vibration, contributing to quieter and more comfortable machinery operation.

Integration with IoT: Integration of sliding bearings into the Internet of Things (IoT) networks allows for remote monitoring and optimization of bearing performance.

Digital Twin Technology: Digital twin simulations are being used to model sliding bearing behavior, aiding in design optimization and performance prediction.

Efficiency in High-Temperature Environments: Advancements in heat-resistant materials have enabled sliding bearings to operate efficiently in high-temperature industrial applications.

These advancements collectively contribute to the evolution of sliding bearing technology, making them more reliable, durable, and adaptable to a wide range of industrial and commercial applications.

Enhancing Efficiency of Marine Propulsion Systems with Sliding Bearings

Sliding bearings play a crucial role in enhancing the efficiency of marine propulsion systems and various ship components. Here’s how sliding bearings contribute to the efficiency of maritime applications:

Reduced Friction: Sliding bearings are designed to minimize friction between moving parts. In marine propulsion systems, such as propeller shafts and stern tubes, reduced friction results in less energy loss and improved fuel efficiency.

Smooth Operation: Sliding bearings provide smooth and controlled movement of rotating or linear components. In marine applications, this smooth operation translates to improved maneuverability, reduced vibrations, and enhanced overall performance.

Load Distribution: Sliding bearings distribute loads evenly across bearing surfaces. This even distribution helps prevent localized wear and reduces the risk of premature failure, ensuring reliable operation of ship components.

Resistance to Harsh Environments: Marine environments expose equipment to corrosive saltwater, extreme temperatures, and harsh weather conditions. Sliding bearings are often designed with materials and coatings that offer corrosion resistance and durability, ensuring longevity even in challenging maritime settings.

Enhanced Lubrication: Lubrication is vital for reducing wear and friction in sliding bearings. Many marine applications use advanced lubrication systems that optimize the distribution of lubricants, further reducing friction and improving efficiency.

Space Efficiency: Sliding bearings are compact and require minimal space, making them suitable for marine systems where space is limited. This efficient use of space is particularly important in ship design and layout.

Customization for Specific Needs: Sliding bearings can be tailored to meet the specific requirements of different ship components. This customization ensures that bearings are optimized for their intended functions, further contributing to efficiency.

Reduced Maintenance: Properly designed sliding bearings require less maintenance compared to some other types of bearings. This reduced maintenance need translates to less downtime and increased operational efficiency for marine vessels.

Optimized Performance: Overall, the efficient and reliable performance of sliding bearings in marine propulsion systems and ship components leads to improved energy efficiency, reduced operational costs, and extended service life of the equipment.

By incorporating sliding bearings into marine applications, shipbuilders and operators can achieve enhanced efficiency, reliability, and sustainability in their operations.

Common Applications and Industries of Sliding Bearings

Sliding bearings are utilized across a wide range of applications and industries due to their unique advantages. Some common applications and industries where sliding bearings are commonly used include:

- Automotive Industry: Sliding bearings are found in engines, transmissions, suspension systems, and various automotive components.

- Industrial Machinery: They are used in manufacturing equipment, conveyors, printing machines, and more.

- Power Generation: Sliding bearings are crucial in turbines, generators, and power transmission systems.

- Aerospace: They play a role in aircraft landing gear, control systems, and propulsion mechanisms.

- Marine: Sliding bearings are used in ship engines, propellers, and steering systems.

- Construction and Mining: They are found in heavy machinery, excavators, loaders, and construction equipment.

- Oil and Gas: Sliding bearings are used in drilling rigs, pumps, compressors, and refineries.

- Railway: They are employed in locomotives, train wheels, and rail systems.

- Medical Equipment: Sliding bearings are used in medical devices, imaging equipment, and surgical instruments.

- Textile Industry: They play a role in weaving machines, spinning frames, and looms.

- Food and Beverage: Sliding bearings are utilized in food processing equipment and packaging machinery.

- Renewable Energy: They are used in wind turbines, solar tracking systems, and other renewable energy applications.

Sliding bearings provide reliable support and smooth motion in various environments, making them essential components in a wide range of industries.

editor by CX 2024-02-25

China Best Sales CZPT Black Phosphating Radial Spherical Plain Bearings Ge 15 Es 2RS bearing air

Product Description

Bearings

SGJ Black Phosphating Radial Spherical Plain Bearings GE 15 ES 2RS

Spherical plain bearingThe spherical plain bearing is a spherical sliding bearing. Its sliding contact surface is an inner spherical surface and an outer spherical surface. It can rotate and swing at any angle during movement. It adopts surface phosphating, frying, inlaying, spraying and other special processes. Method made. Joint bearings have the characteristics of large load capacity, impact resistance, corrosion resistance, wear resistance, self-aligning and good lubrication. Joint bearings can withstand larger loads. According to its different types and structures, it can bear radial load, axial load or a combined load of both radial and axial. Because the outer spherical surface of the inner ring is inlaid with CZPT materials, the bearing can produce self-lubrication during operation. It is generally used for low-speed swing motion and low-speed rotation. It can also be used for tilting motion within a certain angle range. When the support shaft and the shaft housing hole have a large misalignment, it can still work normally. Self-lubricating joint bearings are used in water conservancy, professional machinery and other industries.

| SGJ Radial Spherical Plain Bearings GE Series | |||||||||||||

| No. | Items | Model | Dimensions(mm) | Load Ratings | Weight | ||||||||

| d | D | B | C | dk | r1 min | r2 min | α | Dynamic | Static | (Kg) | |||

| (KN) | (KN) | ||||||||||||

| 1 | GE15ES | GE15ES 2RS | 15 | 26 | 12 | 9 | 22 | 0.3 | 0.3 | 8 | 16 | 84 | 0.571 |

| 2 | GE17ES | GE17ES 2RS | 17 | 30 | 14 | 10 | 25 | 0.3 | 0.3 | 10 | 21 | 106 | 0.041 |

| 3 | GE20ES | GE20ES 2RS | 20 | 35 | 16 | 12 | 29 | 0.3 | 0.3 | 9 | 30 | 146 | 0.066 |

| 4 | GE25ES | GE25ES 2RS | 25 | 42 | 20 | 16 | 35.5 | 0.6 | 0.6 | 7 | 48 | 240 | 0.119 |

| 5 | GE30ES | GE30ES 2RS | 30 | 47 | 22 | 18 | 40.7 | 0.6 | 0.6 | 6 | 62 | 310 | 0.153 |

| 6 | GE35ES | GE35ES 2RS | 35 | 55 | 25 | 20 | 47 | 0.6 | 1 | 6 | 79 | 399 | 0.233 |

| 7 | GE40ES | GE40ES 2RS | 40 | 62 | 28 | 22 | 53 | 0.6 | 1 | 7 | 99 | 495 | 0.306 |

| 8 | GE45ES | GE45ES 2RS | 45 | 68 | 32 | 25 | 60 | 0.6 | 1 | 7 | 127 | 637 | 0.427 |

| 9 | GE50ES | GE50ES 2RS | 50 | 75 | 35 | 28 | 66 | 0.6 | 1 | 6 | 156 | 780 | 0.546 |

| 10 | GE60ES | GE60ES 2RS | 60 | 90 | 44 | 36 | 80 | 1 | 1 | 6 | 245 | 1220 | 1.04 |

| 11 | GE70ES | GE70ES 2RS | 70 | 105 | 49 | 40 | 92 | 1 | 1 | 6 | 313 | 1560 | 1.55 |

| 12 | GE80ES | GE80ES 2RS | 80 | 120 | 55 | 45 | 105 | 1 | 1 | 6 | 400 | 2000 | 2.31 |

| 13 | GE90ES | GE90ES 2RS | 90 | 130 | 60 | 50 | 115 | 1 | 1 | 5 | 488 | 2440 | 2.75 |

| 14 | GE100ES | GE100ES 2RS | 100 | 150 | 70 | 55 | 130 | 1 | 1 | 7 | 607 | 3030 | 4.45 |

| 15 | GE110ES | GE110ES 2RS | 110 | 160 | 70 | 55 | 140 | 1 | 1 | 6 | 654 | 3270 | 4.82 |

| 16 | GE120ES | GE120ES 2RS | 120 | 180 | 85 | 70 | 160 | 1 | 1 | 6 | 950 | 4750 | 8.05 |

| 17 | GE140ES | GE140ES 2RS | 140 | 210 | 90 | 70 | 180 | 1 | 1 | 7 | 1070 | 5350 | 11.02 |

| 18 | GE160ES | GE160ES 2RS | 160 | 230 | 105 | 80 | 200 | 1 | 1 | 8 | 1360 | 6800 | 14.01 |

| 19 | GE180ES | GE180ES 2RS | 180 | 260 | 105 | 80 | 225 | 1.1 | 1.1 | 6 | 1530 | 7650 | 18.65 |

| 20 | GE190ES | GE200ES 2RS | 200 | 290 | 130 | 100 | 250 | 1.1 | 1.1 | 7 | 2120 | 10600 | 28.03 |

| 21 | GE220ES | GE220ES 2RS | 220 | 320 | 135 | 100 | 275 | 1.1 | 1.1 | 8 | 2320 | 11600 | 35.51 |

| 22 | GE240ES | GE240ES 2RS | 240 | 340 | 140 | 100 | 300 | 1.1 | 1.1 | 8 | 2550 | 12700 | 39.91 |

| Contact Angle: | Customized |

|---|---|

| Aligning: | Aligning Bearing |

| Separated: | Separated |

| Rows Number: | Customized |

| Load Direction: | Radial Bearing |

| Material: | Ceramic |

| Samples: |

US$ 11/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What is a bushing?

If you’ve ever wondered what an enclosure is, you’ve come to the right place. This article will provide an overview of different types of housings, including air-insulated, oil-impregnated porous bronze, and epoxy-impregnated capacitor cells. After reading this article, you will be better equipped to make an informed choice about the type of bushings your truck needs.

air insulating sleeve

When choosing bushings for your electrical application, you need to look for bushings with long-lasting insulation. In addition to being durable, bushings must have the correct design shape and material to remain effective over time. Porcelain was used in early casing designs and was chosen for indoor and outdoor applications due to its low cost and low linear expansion. Porcelain also requires a lot of metal fittings and flexible seals to remain effective.

Solid bushings have a center conductor and a porcelain or epoxy insulator. They are used in low voltage electrical applications such as small distribution transformers and circuit switches. However, their low radial capacity limits their use in high-voltage applications, so they are limited to circuit switches and other low-voltage equipment. The electrical service duty of the bushing determines the type of insulation required.

Another type of air-insulated bushing is made of conductive metal, which reduces heat transfer. This design enables it to operate over a range of temperature conditions. Additionally, air-insulated bushings are generally more effective than gas-insulated bushings in a range of applications. The main difference between air-insulated bushings and gas-insulated bushings is the insulating material. While gas-insulated bushings are usually made of high-quality materials, high-quality materials are still preferred in some applications.

Elliott # B series insulators are 25 kV class and pressure molded cycloaliphatic epoxy resins. They feature knurled brass inserts and 16 UNC threads. If you choose this type, make sure it matches the exact diameter of your Elliott Class 25 kv air insulated bushing. These insulators also provide overall shielding and require openings to fit inch diameters.

There are two types of air-insulated bushings: air-to-air and oil-to-oil. Oil is a stronger dielectric than air, and air-to-oil bushings are used to connect atmospheric air to oil-filled equipment. They are available for solid and capacitive hierarchies. So, which one is right for you? Just choose the right insulation to make your equipment as efficient as possible.

Oil Impregnated Porous Bronze Bushings

Oil-impregnated porous bronze (PbB) bushings are one of the best options for lubricating metal bearings. Lubrication is maintained even in high temperature applications as oil penetrates into the pores of the bronze. They are also self-lubricating and maintenance-free. Manufactured by CZPT, the Oil Impregnated Bronze Bushing is a powder metal process that is uniformly lubricated by a uniform oil film. This type of bearing is one of the most efficient in terms of precision performance.

One major difference between oil-impregnated bronze bushings and standard cast bronze bushings is their manufacturing process. Oil-impregnated bronze bushings are pressed from powder and then sintered to form a hardened part. This method is very effective for high-volume manufacturing, but it also has its limitations. Oil-impregnated bronze bushings are cheaper and more efficient, but they have mechanical limitations.

The production of oil-impregnated porous bronze bushings is simple. Powder bronze bushings are pressed and vacuum sealed by forcing oil into the pores. The low stress properties of oil-impregnated bronze bushings make them easier to manufacture in high volume. It also does not require additional lubrication. However, oil-impregnated porous bronze bushings have relatively low mechanical strength and are not recommended for applications where high temperatures are present.

Oil Impregnated Porous Bronze is also known as BPPB. Unlike traditional oil-impregnated bronze bushings, BPPB bushings have a high oil retention capacity. This means they will last a long time and you will save a lot of maintenance costs. But be careful. Porous bronze bushings can only last so long without oil.

Oil-impregnated bronze bushings are a good choice if dimensional consistency is important. BP bronze bushings have the same C dimension as solid metal bushings. While the CZPT is a ghost of the past, there are now many powder metal manufacturers producing BP housings. Their C of F values range from 0.04 to 0.08.

Epoxy Impregnated Capacitor Batteries

Epoxy impregnated condenser core sleeves are conductive paper used in air conditioning systems. The paper core is coated with epoxy resin and the insulating shell is silicone rubber. RIP bushings have excellent electrical properties, are fire resistant and are relatively small. However, the process of making these products is not easy and mistakes are common. These defects manifest as cracks or other structural damage in the capacitor cells.

RIF (Resin Impregnated) bushings feature a finely graded design. The capacitor core is made of glass fiber impregnated with epoxy resin. The outer insulation is made of silicone rubber sheds glued directly to the capacitor core. These bushings are designed for small clearances, so no filler material is required.

In order to determine whether the RIP sleeve is void-free and dry, the insulating paper must be impregnated with epoxy resin. The process is similar to making conventional condenser core sleeves, but with greater flexibility and robustness. The main difference between RIP bushings and conventional insulators is the epoxy content.

Capacitor grading bushings are also available. These bushings increase the electric field at the ends of the capacitor core plates. The higher the temperature, the higher the electric field. These properties make resin-impregnated capacitor mandrel sleeves reliable. However, capacitor grade bushings have higher electric fields than nonlinear bushings.

The capacitor core of the present invention is made by winding paper around the winding tube 3 . The paper may contain an intermediate conductive foil. The winding tube is then covered with electrical insulator. Afterwards, the capacitor core 1 will be RIP and electrically connected to the electrical conductor 6 .

To further characterize the performance of RIPs, thermal shock current (TSC) was used to determine their trap parameters. Unmodified epoxy resin and nano-SiO2 modified RIP were tested. The RIP samples were polarized under a 2 kV/mm electric field at 333 K for 10 min and then subcooled to 193 K with liquid nitrogen. TSC curves were obtained at 3 K/min and 383 K.

plastic bushing

Plastic bushings are essential for many industries. They protect wires and other mechanical parts. They come in many shapes and sizes and are often used as adapters when connecting two pipes or tubes of different diameters. They are available in a variety of materials including rubber, steel and various other plastics. Most bushings are cylindrical or conical in shape and made of shock absorbing material. They slide on rods or pipes to provide low friction motion.

Plastic bushings can be made from a variety of materials, including phenolic, polyethylene, and nylon. While phenolic resins have long been the preferred choice for heavy-duty applications, nylon is the most commonly used lining plastic. Nylon has several advantages, including low friction, no lubrication, quiet operation, and low wear. In addition to these advantages, it is easy to form and cast. In order to obtain better mechanical properties, fillers such as molybdenum disulfide can be added to the material. Plus, filled nylon parts resist deformation at temperatures up to 300 degrees Fahrenheit.

Another benefit of plastic bushings is their low cost. Much cheaper than metal, plastic is a versatile material that can be used in a variety of industries. A quick installation and replacement process makes them the first choice for users who need to install new components quickly. Plus, plastic bushings don’t wear out as quickly as metal, which is another benefit. And because the wear rate of plastic bushings is predictable, manufacturers can easily replace them before they start to fail. And they last longer, so you save time and money.

Plastic bushings are widely used in machinery with sliding and rotating shaft components. They have excellent load-carrying capacity and anti-friction properties. They are essential to many industries, including construction, mining, agriculture, hydropower, transportation and food processing. They are easy to install and come in a variety of sizes and shapes. They are very durable and very reliable. They reduce machine wear and are less expensive than bearings.

editor by CX 2023-05-22

China Best Sales CZPT Black Phosphating Radial Spherical Plain Bearings Ge 15 Es 2RS bearing driver kit

Product Description

Bearings

SGJ Black Phosphating Radial Spherical Plain Bearings GE 15 ES 2RS

Spherical plain bearingThe spherical plain bearing is a spherical sliding bearing. Its sliding contact surface is an inner spherical surface and an outer spherical surface. It can rotate and swing at any angle during movement. It adopts surface phosphating, frying, inlaying, spraying and other special processes. Method made. Joint bearings have the characteristics of large load capacity, impact resistance, corrosion resistance, wear resistance, self-aligning and good lubrication. Joint bearings can withstand larger loads. According to its different types and structures, it can bear radial load, axial load or a combined load of both radial and axial. Because the outer spherical surface of the inner ring is inlaid with CZPT materials, the bearing can produce self-lubrication during operation. It is generally used for low-speed swing motion and low-speed rotation. It can also be used for tilting motion within a certain angle range. When the support shaft and the shaft housing hole have a large misalignment, it can still work normally. Self-lubricating joint bearings are used in water conservancy, professional machinery and other industries.

| SGJ Radial Spherical Plain Bearings GE Series | |||||||||||||

| No. | Items | Model | Dimensions(mm) | Load Ratings | Weight | ||||||||

| d | D | B | C | dk | r1 min | r2 min | α | Dynamic | Static | (Kg) | |||

| (KN) | (KN) | ||||||||||||

| 1 | GE15ES | GE15ES 2RS | 15 | 26 | 12 | 9 | 22 | 0.3 | 0.3 | 8 | 16 | 84 | 0.571 |

| 2 | GE17ES | GE17ES 2RS | 17 | 30 | 14 | 10 | 25 | 0.3 | 0.3 | 10 | 21 | 106 | 0.041 |

| 3 | GE20ES | GE20ES 2RS | 20 | 35 | 16 | 12 | 29 | 0.3 | 0.3 | 9 | 30 | 146 | 0.066 |

| 4 | GE25ES | GE25ES 2RS | 25 | 42 | 20 | 16 | 35.5 | 0.6 | 0.6 | 7 | 48 | 240 | 0.119 |

| 5 | GE30ES | GE30ES 2RS | 30 | 47 | 22 | 18 | 40.7 | 0.6 | 0.6 | 6 | 62 | 310 | 0.153 |

| 6 | GE35ES | GE35ES 2RS | 35 | 55 | 25 | 20 | 47 | 0.6 | 1 | 6 | 79 | 399 | 0.233 |

| 7 | GE40ES | GE40ES 2RS | 40 | 62 | 28 | 22 | 53 | 0.6 | 1 | 7 | 99 | 495 | 0.306 |

| 8 | GE45ES | GE45ES 2RS | 45 | 68 | 32 | 25 | 60 | 0.6 | 1 | 7 | 127 | 637 | 0.427 |

| 9 | GE50ES | GE50ES 2RS | 50 | 75 | 35 | 28 | 66 | 0.6 | 1 | 6 | 156 | 780 | 0.546 |

| 10 | GE60ES | GE60ES 2RS | 60 | 90 | 44 | 36 | 80 | 1 | 1 | 6 | 245 | 1220 | 1.04 |

| 11 | GE70ES | GE70ES 2RS | 70 | 105 | 49 | 40 | 92 | 1 | 1 | 6 | 313 | 1560 | 1.55 |

| 12 | GE80ES | GE80ES 2RS | 80 | 120 | 55 | 45 | 105 | 1 | 1 | 6 | 400 | 2000 | 2.31 |

| 13 | GE90ES | GE90ES 2RS | 90 | 130 | 60 | 50 | 115 | 1 | 1 | 5 | 488 | 2440 | 2.75 |

| 14 | GE100ES | GE100ES 2RS | 100 | 150 | 70 | 55 | 130 | 1 | 1 | 7 | 607 | 3030 | 4.45 |

| 15 | GE110ES | GE110ES 2RS | 110 | 160 | 70 | 55 | 140 | 1 | 1 | 6 | 654 | 3270 | 4.82 |

| 16 | GE120ES | GE120ES 2RS | 120 | 180 | 85 | 70 | 160 | 1 | 1 | 6 | 950 | 4750 | 8.05 |

| 17 | GE140ES | GE140ES 2RS | 140 | 210 | 90 | 70 | 180 | 1 | 1 | 7 | 1070 | 5350 | 11.02 |

| 18 | GE160ES | GE160ES 2RS | 160 | 230 | 105 | 80 | 200 | 1 | 1 | 8 | 1360 | 6800 | 14.01 |

| 19 | GE180ES | GE180ES 2RS | 180 | 260 | 105 | 80 | 225 | 1.1 | 1.1 | 6 | 1530 | 7650 | 18.65 |

| 20 | GE190ES | GE200ES 2RS | 200 | 290 | 130 | 100 | 250 | 1.1 | 1.1 | 7 | 2120 | 10600 | 28.03 |

| 21 | GE220ES | GE220ES 2RS | 220 | 320 | 135 | 100 | 275 | 1.1 | 1.1 | 8 | 2320 | 11600 | 35.51 |

| 22 | GE240ES | GE240ES 2RS | 240 | 340 | 140 | 100 | 300 | 1.1 | 1.1 | 8 | 2550 | 12700 | 39.91 |

| Contact Angle: | Customized |

|---|---|

| Aligning: | Aligning Bearing |

| Separated: | Separated |

| Rows Number: | Customized |

| Load Direction: | Radial Bearing |

| Material: | Ceramic |

| Samples: |

US$ 11/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Types of Ball Bearings

There are several types of ball bearings: Double-row angular contact, Four-point contact, Self-aligning, and Ceramic hybrid. Here’s a brief description of each. For more information, read our article about Double-row angular contact ball bearings. You’ll be better informed about how they’re made. Also, learn about how the cages that hold the balls in place are secured with rivets.

Double-row, angular-contact bearing

Double-row, angular-contact ball bearings are similar in their contact surfaces in one direction, and the two pairs of bearings are installed axially opposite to one another. This design allows them to support combined loads in axial and radial directions. These types of bearings are used for high-precision, high-speed applications. They can be used in everything from turbines to dentistry equipment. Double-row, angular-contact bearings are available at Grainger, as are single-row versions.

Double-row, angular-contact ball bearings are a popular option for applications where high precision and high speed are required. The design features of these bearings are ideal for applications with axial space restrictions. In contrast, they are smaller than two single-row angular-contact bearings and are available in steel, polyamide, or brass cages. Whether you need a cage for high speed or hard operating conditions is up to you. If you are unsure about the right cage for your application, contact Schaeffler.

Single-row angular-contact ball bearings are the most common type of bearings. Double-row bearings are also available with a shielded outer ring, which protects the balls inside the bearing from external contaminants. Because these double-row bearings are a good choice for applications requiring high performance, they are often the most affordable option. They offer similar performance as single-row bearings but are much more rigid.

Preloading is a key performance characteristic for double-row angular-contact ball bearings. Preloading can decrease the service life of double-row angular-contact ball bearings by up to 380 percent. Alternatively, you can preload double-row angular-contact ball bearings by placing spacers between their outer rings. Good double-row angular-contact bearing installation will increase working accuracy and bearing life.

Four-point contact ball bearing

The Four Point Contact Ball Bearing Market can be segmented into three types: 35 Degree, 45 Degree, and Other. The 35 Degree segment is expected to witness the fastest growth over the next few years, owing to its increased operational speed and competence in axial and radial axis load handling. Other types of four-point contact ball bearings include the Miniature and Deep Groove varieties. These are widely used in automobiles, aerospace, and other industries.

These bearings are designed for oil-free screw compressors, and they feature an outer-ring guided brass cage to reduce friction and increase running accuracy. In addition, they have lower maintenance costs compared to conventional bearings. However, they have a higher mean roughness value than their counterparts. High-speed operations require high-speed bearings that can withstand fast speed changes. This is because of the higher friction rate, which results from four-point contact.

The Four-Point Contact Ball Bearing is a highly versatile product, as it can handle radial, thrust, and moment loads. Because of this, it is often the first choice for slow to moderate-speed applications. This design also has a simplified assembly process, requiring only a single double-half-turn to install. It is the first choice of many automotive OEMs because it is extremely efficient. If you want a ball bearing with these benefits, you should contact a local bearing company.

The Four-Point Contact Ball Bearing Market will continue to grow despite a tough economy and volatile trade conditions. Demand for automotive and aerospace components is expected to grow alongside a variety of technological advancements. Meanwhile, demand for energy-efficient products will continue to increase with changes in trade policy, an imbalance in the supply-side ecosystem, and geopolitical risk. And while all these factors will continue to drive the market growth, a few challenges are worth considering.

The Four-Point Contact Bearing is designed with the same basic structure as its two-point counterpart. In a four-point contact ball bearing, one ball can have four distinct points of contact with two rings. Two of these contact points may be in diagonal position. The two remaining contact points change position and accommodate radial loads. Consequently, the Four-Point Contact Bearing is more flexible and robust than its two-point counterparts.

Self-aligning ball bearing

The self-aligning ball bearing is an incredibly useful tool in many industries. This type of bearing has a sealing lip that makes contact with a smooth chamfer on the inner ring. Because of the self-aligning nature of these bearings, they are not prone to misalignment. They can withstand temperatures ranging from -30°C to 120°C and should not be heated prior to installation.

A self-aligning ball bearing is an elastomer-based spherical-shaped bearing with two rows of rolling elements. These bearings can accommodate large radial loads, and their outer ring raceway is curved to provide a spherical effect. The inner ring, or cage, can be either cylindrical or conical. The inner diameter of a self-aligning ball bearing is normally cylindrical, but some are conical. They typically have three oil holes.

When choosing a self-aligning ball bearing, look for a model with a large enough bearing diameter to accommodate the shaft’s bending. Self-aligning bearings may also be interchangeable with standard ball bearing assemblies. You can find individual values in manufacturer catalogues. These bearings are useful in limited applications, although they are not necessarily ideal for everything. For example, in applications where combined loads are the main concern, self-aligning ball bearings should only be used if the application requires minimal misalignment.

A self-aligning ball bearing is a highly-efficient, energy-efficient solution for a variety of applications. It is a simple, low-maintenance solution that makes your life easier. Its unique outer raceway allows restraining springs to absorb the deflection that is common in other bearings. The result is a cooler, smoother running vehicle. It also helps prevent misalignment, which makes it ideal for use in many applications.

The SKF self-aligning ball bearing is an excellent choice for applications involving heavy deflection of the shaft. They are the lowest-friction bearing available. Their steel plate reinforced seals prevent them from separating from the shaft during operation. They are also resistant to oil, making them the perfect solution for high-speed applications. In addition to this, they are designed to work in a wide range of temperatures.

Ceramic hybrid ball bearing

A hybrid ball bearing made from a combination of steel and ceramics is a good option for high-speed applications requiring electrical isolation. This combination offers an extended lifespan and minimal electrical corrosion or seizure risk. In addition, the hybrid ball bearings have less friction than steel bearings and can operate at low speeds. To learn more about this hybrid type of bearing, continue reading. We’ll also discuss how it can help your application.

Full ceramic balls are generally harder than steel, but they do have lower density, meaning they’re not subject to the same high centrifugal forces as steel balls. These benefits make ceramic ball bearings much more durable, with long lifespans. Both full and hybrid ceramic ball bearings are available from CZPT. Read on to learn more about each type. Here’s a look at some of the benefits of each. You’ll be pleasantly surprised.

A hybrid ball bearing consists of steel inner and outer rings and a ceramic ball. It can withstand high speeds and loads, but it’s also designed to operate in extreme temperatures. This hybrid ball bearing also requires minimal lubrication and is suitable for a variety of applications. Because of its unique characteristics, hybrid bearings are lightweight and hard, and they spin faster than steel balls. But how do you choose the right one for your application?

A ceramic ball bearing is better than a steel one for many applications. Its greater speed capability and lower friction allow it to operate at higher speeds than steel balls. It is also less sensitive to fluctuations in lubrication conditions than steel balls. They also tend to be cheaper, so it makes sense to invest in one. It’s worth your while. They last longer, and they don’t require a run-in period.

A hybrid ball bearing is the best choice for electric spindles with high speed and heavy loads. A hybrid ceramic ball bearing has the advantage of low heat and high stiffness, and can operate at high speeds and loads. This thesis explores the dynamic characteristics of a hybrid ceramic ball bearing, including analysis calculations and experiment verification. The results provide reliable data and lay the foundation for professional spindle optimum design tests. It is a worthy addition to any machine shop.

editor by CX 2023-05-19

China best CZPT Black Phosphating Radial Spherical Plain Bearings Ge 15 Es 2RS double row ball bearing

Product Description

Bearings

SGJ Black Phosphating Radial Spherical Plain Bearings GE 15 ES 2RS

Spherical plain bearingThe spherical plain bearing is a spherical sliding bearing. Its sliding contact surface is an inner spherical surface and an outer spherical surface. It can rotate and swing at any angle during movement. It adopts surface phosphating, frying, inlaying, spraying and other special processes. Method made. Joint bearings have the characteristics of large load capacity, impact resistance, corrosion resistance, wear resistance, self-aligning and good lubrication. Joint bearings can withstand larger loads. According to its different types and structures, it can bear radial load, axial load or a combined load of both radial and axial. Because the outer spherical surface of the inner ring is inlaid with CZPT materials, the bearing can produce self-lubrication during operation. It is generally used for low-speed swing motion and low-speed rotation. It can also be used for tilting motion within a certain angle range. When the support shaft and the shaft housing hole have a large misalignment, it can still work normally. Self-lubricating joint bearings are used in water conservancy, professional machinery and other industries.

| SGJ Radial Spherical Plain Bearings GE Series | |||||||||||||

| No. | Items | Model | Dimensions(mm) | Load Ratings | Weight | ||||||||

| d | D | B | C | dk | r1 min | r2 min | α | Dynamic | Static | (Kg) | |||

| (KN) | (KN) | ||||||||||||

| 1 | GE15ES | GE15ES 2RS | 15 | 26 | 12 | 9 | 22 | 0.3 | 0.3 | 8 | 16 | 84 | 0.571 |

| 2 | GE17ES | GE17ES 2RS | 17 | 30 | 14 | 10 | 25 | 0.3 | 0.3 | 10 | 21 | 106 | 0.041 |

| 3 | GE20ES | GE20ES 2RS | 20 | 35 | 16 | 12 | 29 | 0.3 | 0.3 | 9 | 30 | 146 | 0.066 |

| 4 | GE25ES | GE25ES 2RS | 25 | 42 | 20 | 16 | 35.5 | 0.6 | 0.6 | 7 | 48 | 240 | 0.119 |

| 5 | GE30ES | GE30ES 2RS | 30 | 47 | 22 | 18 | 40.7 | 0.6 | 0.6 | 6 | 62 | 310 | 0.153 |

| 6 | GE35ES | GE35ES 2RS | 35 | 55 | 25 | 20 | 47 | 0.6 | 1 | 6 | 79 | 399 | 0.233 |

| 7 | GE40ES | GE40ES 2RS | 40 | 62 | 28 | 22 | 53 | 0.6 | 1 | 7 | 99 | 495 | 0.306 |

| 8 | GE45ES | GE45ES 2RS | 45 | 68 | 32 | 25 | 60 | 0.6 | 1 | 7 | 127 | 637 | 0.427 |

| 9 | GE50ES | GE50ES 2RS | 50 | 75 | 35 | 28 | 66 | 0.6 | 1 | 6 | 156 | 780 | 0.546 |

| 10 | GE60ES | GE60ES 2RS | 60 | 90 | 44 | 36 | 80 | 1 | 1 | 6 | 245 | 1220 | 1.04 |

| 11 | GE70ES | GE70ES 2RS | 70 | 105 | 49 | 40 | 92 | 1 | 1 | 6 | 313 | 1560 | 1.55 |

| 12 | GE80ES | GE80ES 2RS | 80 | 120 | 55 | 45 | 105 | 1 | 1 | 6 | 400 | 2000 | 2.31 |

| 13 | GE90ES | GE90ES 2RS | 90 | 130 | 60 | 50 | 115 | 1 | 1 | 5 | 488 | 2440 | 2.75 |

| 14 | GE100ES | GE100ES 2RS | 100 | 150 | 70 | 55 | 130 | 1 | 1 | 7 | 607 | 3030 | 4.45 |

| 15 | GE110ES | GE110ES 2RS | 110 | 160 | 70 | 55 | 140 | 1 | 1 | 6 | 654 | 3270 | 4.82 |

| 16 | GE120ES | GE120ES 2RS | 120 | 180 | 85 | 70 | 160 | 1 | 1 | 6 | 950 | 4750 | 8.05 |

| 17 | GE140ES | GE140ES 2RS | 140 | 210 | 90 | 70 | 180 | 1 | 1 | 7 | 1070 | 5350 | 11.02 |

| 18 | GE160ES | GE160ES 2RS | 160 | 230 | 105 | 80 | 200 | 1 | 1 | 8 | 1360 | 6800 | 14.01 |

| 19 | GE180ES | GE180ES 2RS | 180 | 260 | 105 | 80 | 225 | 1.1 | 1.1 | 6 | 1530 | 7650 | 18.65 |

| 20 | GE190ES | GE200ES 2RS | 200 | 290 | 130 | 100 | 250 | 1.1 | 1.1 | 7 | 2120 | 10600 | 28.03 |

| 21 | GE220ES | GE220ES 2RS | 220 | 320 | 135 | 100 | 275 | 1.1 | 1.1 | 8 | 2320 | 11600 | 35.51 |

| 22 | GE240ES | GE240ES 2RS | 240 | 340 | 140 | 100 | 300 | 1.1 | 1.1 | 8 | 2550 | 12700 | 39.91 |

| Contact Angle: | Customized |

|---|---|

| Aligning: | Aligning Bearing |

| Separated: | Separated |

| Rows Number: | Customized |

| Load Direction: | Radial Bearing |

| Material: | Ceramic |

| Samples: |

US$ 11/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Understanding the Different Types of Bearings

When you are looking for a bearing, you have many options to choose from. This article will explain the various types, functions, and working principles of different types of bearings. Once you understand the basic components, you can make an informed decision about which one to buy. Here’s an overview of some of the most common types. Learn more about each type below! Read on to learn about the differences between these different types of bearings! Posted in Articles

Functions

Bearings serve as an integral part of a mechanical device. These devices help transfer torque from one part of a structure to another. These mechanisms increase the efficiency of a shaft by increasing its life. However, the functions of bearings depend on the application of the structure. Among other functions, bearings provide support to shafts. Anti-friction bearings come in two types: ball and roller bearings. These components have line and point contact, which is the most common type. Archimedes’s principle states that the force is equal to the weight of the fluid that is being displaced. Bearings can transfer lateral loads to a substructure.