Product Description

Product Description

Specifications

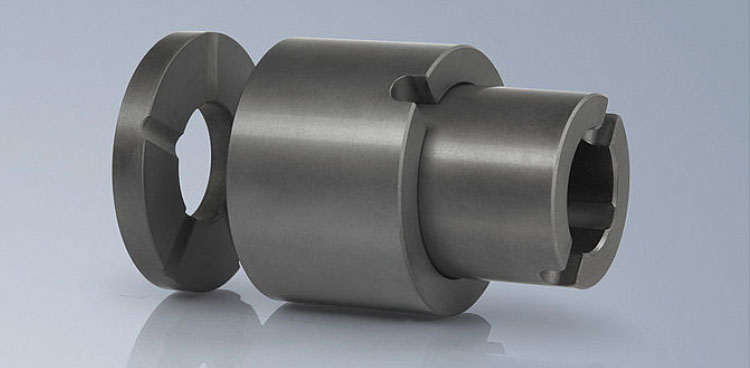

Linear bearings Lm 35uu

1.Color:silver

2.Linear bearing material:bearing steel Gcr15

3.Applied in:mechanic

4.Smooth movement,low friction,high rigidity and long life

5.We can make non-standard linear bearing according to clients samples of drawing.

6.prompt delivery

7.we supply OEM service.

8.Nice appearance,complete product system.

Linear bearing specifications

“LM” metric standard type linear bearing

“LME” means inch standard type linear bearing

“UU” rubber seals on the both sides of the long type linear bearing

“OP” means open type linear bearing

“AJ” means adjustment type linear bearing

*LM…UU: LM…(sylinder), LM…OP(open type), LM…AJ(clearance adustable)

*LME…UU: LME…(sylinder), LME…OP(open type), LME…AJ(clearance adustable), LM…UU & LME…UU: Long type

*KH: High-precision mini bearing

Image Details:

Items Details

| LM6UU | LM6UU-OP | LM6UU-AJ |

| LM8UU | LM8UU-OP | LM8UU-AJ |

| LM10UU | LM10UU-OP | LM10UU-AJ |

| LM12UU | LM12UU-OP | LM12UU-AJ |

| LM13UU | LM13UU-OP | LM13UU-AJ |

| LM16UU | LM16UU-OP | LM16UU-AJ |

| LM20UU | LM20UU-OP | LM20UU-AJ |

| LM25UU | LM25UU-OP | LM25UU-AJ |

| LM30UU | LM30UU-OP | LM30UU-AJ |

| LM35UU | LM35UU-OP | LM35UU-AJ |

| LM40UU | LM40UU-OP | LM40UU-AJ |

| LM50UU | LM50UU-OP | LM50UU-AJ |

| LM60UU | LM60UU-OP | LM60UU-AJ |

| LM80UU | LM80UU-OP | LM80UU-AJ |

| LM100UU | LM100UU-OP | LM100UU-AJ |

HangZhou JPG BEARING MANUFACTURING IS a professional series linear motion bearing products manufacturer with 10 years experiences,we could offer many kinds of linear bearing and good quality linear bearing.

Delivery:

1. Less than 1000 pcs , we will send by express. ( Door to Door, Convenient ),

or by air transport. ( Fastest and safest, but expensive )

2. More than 1000pcs , we will send by sea. ( Cheapest, safe )

Payment:

1. Less than 1000 pcs , 100% T/T, Western Union in advance.

2. Between 1000-10000pcs, TT, Western Union, MoneyGram.

3. More than 10000pcs , TT, L/C ,Western Union, MoneyGram.

Packaging

1. Neutral Package: Plastic Bag + Carton + Pallet; 2. Commercial Package: Plastic Bag + Box + Carton + Pallet; 3. As the clients’ requirement.

After service

All of our bearings are qualified and manufactured as Chinese Bearing Industry Standard (GB/T 307.2-1995). Any bearing sold has a warranty from us.

To improve our products and service greatly, any feedback of bearings, package, delivery etc would be highly appreciated

In case of any bearing problem, which is caused by bearing quality, package etc, we would like to replace the bearings.

Any other question, feel free to contact us by email.

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Function: | Super |

|---|---|

| Flange Shape: | Oval |

| Shape: | Open |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Differences Between Plain Sliding Bearings and Self-Lubricating Bearings

Plain sliding bearings and self-lubricating bearings are two distinct types of bearings used in various applications. Here are the key differences between them:

Plain Sliding Bearings:

- Plain sliding bearings, also known as bushings, are simple bearing components that consist of a cylindrical sleeve made of a bearing material.

- These bearings require external lubrication, such as grease or oil, to reduce friction and wear between the bearing and the shaft.

- Regular maintenance and lubrication are essential to ensure proper operation and longevity.

- Plain sliding bearings are cost-effective and suitable for applications where lubrication can be easily provided.

- They are commonly used in low-speed and low-load applications, where the shaft slides within the bearing.

Self-Lubricating Bearings:

- Self-lubricating bearings, also known as maintenance-free bearings, are designed to operate without the need for external lubrication.

- These bearings incorporate solid lubricants, such as graphite, PTFE (polytetrafluoroethylene), or other additives, directly into the bearing material.

- The solid lubricants are released gradually as the bearing operates, reducing friction and providing a consistent lubricating film.

- Self-lubricating bearings are ideal for applications where frequent maintenance or lubrication is impractical or not feasible.

- They are suitable for both low-load and high-load applications, as the self-lubricating properties help extend the bearing’s service life.

In summary, plain sliding bearings require external lubrication and are suitable for applications where lubrication can be provided, while self-lubricating bearings incorporate solid lubricants and operate without the need for regular maintenance. The choice between these two types depends on factors such as the application’s operating conditions, maintenance requirements, and budget considerations.

Benefits of Sliding Bearings in Low-Speed and Heavy-Load Applications

Sliding bearings offer significant advantages in low-speed and heavy-load applications, where their unique characteristics provide optimal performance. Some examples of scenarios where sliding bearings benefit such applications include:

- Mining Equipment: Sliding bearings are used in mining machinery such as crushers, mills, and conveyor systems. These applications often involve heavy loads and low speeds, where sliding bearings can provide robust support and reliable operation.

- Steel Mills: In steel production, sliding bearings are utilized in rolling mills and continuous casting machines. These operations require handling heavy loads and slow rotation speeds, making sliding bearings suitable for providing the necessary support.

- Hydraulic Systems: Sliding bearings are used in hydraulic cylinders, where slow and controlled movements are required for applications like construction machinery, material handling equipment, and heavy-duty presses.

- Cranes and Lifts: Sliding bearings are employed in the construction of cranes, elevators, and lifting platforms. These applications involve lifting and lowering heavy loads at controlled speeds, making sliding bearings crucial for smooth and reliable motion.

- Wind Turbines: Sliding bearings are used in the yaw and pitch systems of wind turbines. These systems need to handle the substantial weight of the turbine blades and operate at low speeds to optimize energy generation.

In these scenarios and more, sliding bearings provide the necessary support, stability, and durability required for low-speed and heavy-load applications.

Considerations for Selecting Sliding Bearings

When choosing a sliding bearing for a specific application, several key factors should be taken into consideration:

- Load Capacity: Determine the maximum load the bearing will need to support. This includes both radial and axial loads, as well as any dynamic or static loads.

- Operating Conditions: Consider the operating environment, including temperature, humidity, and exposure to chemicals or contaminants. Different materials and coatings may be required for harsh conditions.

- Lubrication: Choose the appropriate lubrication method based on the application. Consider factors such as the frequency of lubrication, the availability of lubrication points, and the compatibility of lubricants with the bearing material.

- Speed and Motion: Evaluate the speed and type of motion the bearing will experience. Higher speeds may require special considerations for heat dissipation and lubrication.

- Alignment and Misalignment: Determine if the bearing will need to accommodate misalignment between the shaft and the bearing housing. Some applications may require self-aligning or spherical bearings.

- Wear Resistance: Choose a bearing material that offers good wear resistance to prevent premature wear and extend the bearing’s lifespan.

- Noise and Vibration: Consider the impact of noise and vibration on the application. Bearings with proper damping properties can help reduce noise and vibration levels.

- Maintenance Requirements: Assess the ease of maintenance, including lubrication intervals, accessibility of lubrication points, and the need for regular inspections.

- Cost and Availability: Compare the cost of the bearing with its expected performance and lifespan. Also, ensure that the chosen bearing type and size are readily available.

- Application-Specific Considerations: Some applications may have unique requirements, such as corrosion resistance, electrical insulation, or compatibility with food-grade standards.

By carefully considering these factors, you can select a sliding bearing that meets the specific needs of your application, ensuring reliable performance and longevity.

editor by CX 2024-05-07