Product Description

HangZhou CZPT PULLEY MANUFACTURE CO., LTD. has been specialized in manufacturing Plastic Pulley/Rollers, Die-punching Pulley/Bearing, and Non-standard Bearings for about 25 years. It is located in HangZhou city of ZHangZhoug Province, which has convenient transportation benefited from Nignbo Seaport, HangZhou International Airport and the highway networks. Our company covers an area of 7000 m², with building area of 10500 m². Relying on advanced processing equipments and technology, and strict inspection system, our company is CZPT to provide good-quality and competitive products, and has gained a good reputation among customers.

We are committed to developing and designing different kinds of non-standard pulley bearings, with an annual production capacity of 120 million sets. We export to more than 70 countries and areas, like USA, Canada, Spain, Germany, France and Italy, etc.

Our company maintains our quality system to ISO 9001:2000, and has been audited by SGS for our production operations. We will continuously seek to provide our customers with good-quality products, excellent service and most competitive price. We look forward to building long-term business relationship with you and achieving our mutual benefits.

About us

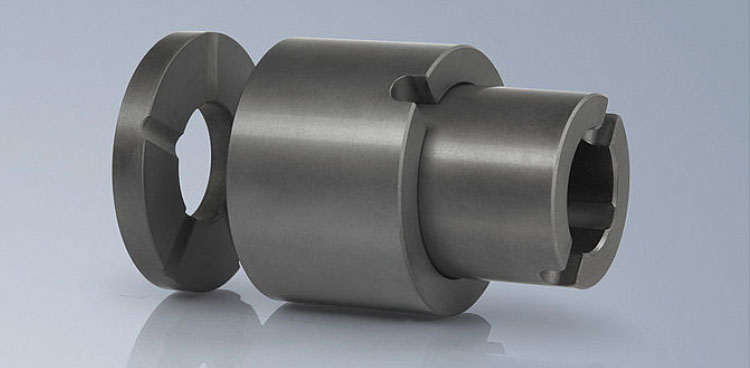

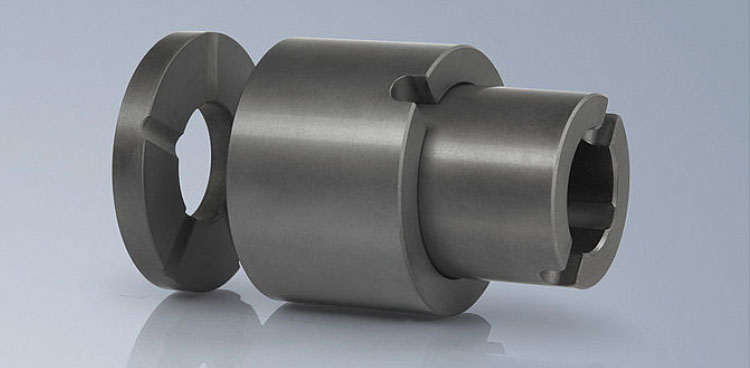

| name | Tight Plastic Bearing with Steel Balls Sliding Bearing Roller with ISO(ML-AU050) |

| Brand name | According to customers’ requirements |

| Size | As per the customer’s technic drawing or samples |

| material | pom,pa6,pa66,nylon,pvc,abs…wheels,Aluminium,Zinc,Stainless steel frame |

| Technical process | bearing production assembling,zinc plating,injection,turning |

| Color | orange,white,black,yellow |

| Types | customized |

| Payment terms | A:100% TT B: 30% T/T in advance .70% against copy of B/L |

| Application | caster wheel , small pulley , window , sliding door ,door closet wardrobe system… |

| Product Description | 1.Item No.: as shown in the picture. 2.Material: steel/zinc/aluminum/plastic bracket + ball bearing / needle bearing wheel 3.For some models, the height of the roller is adjustable. 4.Color of the wheel: red, green, white, orange, etc. 5.Application: sliding door and window, binds, rolling shutters, furniture, conveyor belt, etc. 6.Normal packing: poly bag + outer carton |

Contact Us

HangZhou CZPT Pulley Manufacture Co., Ltd.

WEB: http://nbminli /

ADDRESS: No.9 CZPT Road, CZPT Industrial Zone, Xihu (West Lake) Dis. District, HangZhou, China

Comparable products

FAQ

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a quotaion in the shortest time?

A: When you send us an enquiry, please try to provide more details, such as product size, photo or drawing, order quantity, etc.

Q: How to start an OEM project with your company?

A: Please send us your designed drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange sample production once received your deposit .

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. Nomally our company MOQ is 10000pc , but it can be much more or less depending on different product types. Therefore, we recommend you to tell us your required quantity first.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. The lead time varies from 30 to 90 days.

Why choose us

1.Professional experience: almost 20 years’ expenience in non-standard bearings, rollers, pulleys, and other plastic accessories for door and window.

2.Popular over the world: over 20 market countries.

3.Advantage: good quality with competitive price.

4.OEM offered: technical drawings, samples or photos are needed.

For more information, please visit http://nbminli /

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Ball Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Micro(≤26mm) |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Contribution of Sliding Bearings to Agricultural Machinery and Equipment

Sliding bearings play a crucial role in enhancing the functionality and efficiency of various agricultural machinery and equipment. Here’s how they contribute:

Smooth Movement: Sliding bearings provide smooth and low-friction movement in agricultural machinery, ensuring efficient operation of components like pivots, linkages, and joints.

Load Distribution: Sliding bearings distribute loads evenly across surfaces, reducing stress on components and extending the lifespan of agricultural equipment.

Durability: Sliding bearings are designed to withstand harsh conditions commonly encountered in agriculture, such as exposure to dirt, debris, and moisture.

Low Maintenance: Sliding bearings require minimal maintenance due to their self-lubricating properties, reducing downtime and operational costs.

Vibration Dampening: Sliding bearings help dampen vibrations in agricultural machinery, improving operator comfort and reducing wear on components.

Enhanced Precision: Sliding bearings ensure precise movement in equipment like planting and harvesting machinery, contributing to accurate and consistent operations.

Versatility: Sliding bearings are used in a wide range of agricultural applications, including tractors, combines, plows, irrigation systems, and more.

Cost Efficiency: Sliding bearings provide a cost-effective solution for agricultural machinery, offering long service life and reducing the need for frequent replacements.

Reliability: Sliding bearings offer reliable performance even in challenging agricultural environments, contributing to the overall reliability of the equipment.

Environmental Adaptability: Sliding bearings can handle varying weather conditions and exposure to agricultural chemicals without compromising performance.

Overall, sliding bearings play a vital role in ensuring the smooth operation, durability, and performance of agricultural machinery and equipment, contributing to increased productivity and reduced maintenance requirements in the agriculture sector.

Benefits of Sliding Bearings in Low-Speed and Heavy-Load Applications

Sliding bearings offer significant advantages in low-speed and heavy-load applications, where their unique characteristics provide optimal performance. Some examples of scenarios where sliding bearings benefit such applications include:

- Mining Equipment: Sliding bearings are used in mining machinery such as crushers, mills, and conveyor systems. These applications often involve heavy loads and low speeds, where sliding bearings can provide robust support and reliable operation.

- Steel Mills: In steel production, sliding bearings are utilized in rolling mills and continuous casting machines. These operations require handling heavy loads and slow rotation speeds, making sliding bearings suitable for providing the necessary support.

- Hydraulic Systems: Sliding bearings are used in hydraulic cylinders, where slow and controlled movements are required for applications like construction machinery, material handling equipment, and heavy-duty presses.

- Cranes and Lifts: Sliding bearings are employed in the construction of cranes, elevators, and lifting platforms. These applications involve lifting and lowering heavy loads at controlled speeds, making sliding bearings crucial for smooth and reliable motion.

- Wind Turbines: Sliding bearings are used in the yaw and pitch systems of wind turbines. These systems need to handle the substantial weight of the turbine blades and operate at low speeds to optimize energy generation.

In these scenarios and more, sliding bearings provide the necessary support, stability, and durability required for low-speed and heavy-load applications.

Impact of Proper Lubrication on Sliding Bearings

Proper lubrication plays a critical role in the performance and longevity of sliding bearings. Here’s how it affects their operation:

- Reduced Friction and Wear: Lubrication forms a thin film between the sliding surfaces of the bearing, reducing direct metal-to-metal contact. This minimizes friction and wear, which can significantly extend the bearing’s lifespan.

- Heat Dissipation: Lubricants help dissipate heat generated during operation by carrying away excess heat from the friction zones. This prevents overheating and potential damage to the bearing and surrounding components.

- Corrosion Prevention: Lubricants provide a protective barrier against moisture and corrosive substances, preventing the formation of rust and corrosion on the bearing surfaces.

- Sealing Effect: Proper lubrication can help create a sealing effect that prevents contaminants from entering the bearing, maintaining a clean and efficient operating environment.

- Noise and Vibration Reduction: Adequate lubrication helps dampen noise and reduce vibration caused by friction between bearing surfaces. This contributes to quieter and smoother operation.

- Enhanced Load Distribution: Lubrication ensures even load distribution across the bearing surfaces, preventing localized wear and extending the bearing’s overall life.

- Stability and Performance: Proper lubrication maintains consistent performance and stability by minimizing variations in friction and reducing the risk of sudden failures.

- Seizure Prevention: Lubricants prevent sliding surfaces from seizing or sticking together, even during periods of prolonged inactivity.

- Optimized Efficiency: Well-lubricated bearings experience less energy loss due to friction, resulting in improved overall efficiency of the machinery.

Choosing the right lubricant type, viscosity, and lubrication interval is crucial to ensuring the optimal performance and durability of sliding bearings. Regular maintenance and monitoring of lubrication levels are essential to prevent issues and extend the bearing’s service life.

editor by CX 2024-05-15

China OEM Plastic Pulley/Kobelco Excavator Parts/Sliding Door Rollers/Grease Cartridge/Ball/Roller/Slewing/Pillow Block/Lead Rubber/Nis/Spherical Roller Bearing 32228 drive shaft bearing

Product Description

These bearings are capable of taking high radial loads and axial loads in 1 direction. In the HR series, the rollers are increased in both size and number giving it an even higher load capacity. They are generally mounted in pairs in a manner similar to single-row angular contact ball bearings. In this case, the proper internal clearance can be obtained by adjusting the axial distance between the cones or cups of the 2 opposed bearings.

| Model | Size | Rated dynamic load (KN) | Rated static load (KN) | Weight (kg) | ||

| (mm) | ||||||

| d | D | T | ||||

| 32007 | 35 | 62 | 18 | 43.2 | 59.2 | 0.224 |

| 32008 | 40 | 68 | 19 | 51.9 | 71.1 | 0.268 |

| 32009 | 45 | 75 | 20 | 58.4 | 81.4 | 0.339 |

| 32571 | 50 | 80 | 20 | 61.1 | 89 | 0.367 |

| 32011 | 55 | 90 | 23 | 80.2 | 117.2 | 0.564 |

| 32012 | 60 | 95 | 23 | 81.7 | 122.2 | 0.597 |

| 32013 | 65 | 100 | 23 | 82.8 | 127.3 | 0.628 |

| 32014 | 70 | 110 | 25 | 104.3 | 160.1 | 0.838 |

| 32015 | 75 | 115 | 25 | 103.1 | 160.2 | 0.875 |

| 32016 | 80 | 125 | 29 | 141 | 220 | 1.27 |

| 32017 | 85 | 130 | 29 | 139.8 | 220.3 | 1.33 |

| 32018 | 90 | 140 | 32 | 171.3 | 271 | 1.77 |

| 32019 | 95 | 145 | 32 | 174.6 | 281.3 | 1.796 |

| 32571 | 100 | 150 | 32 | 173.1 | 281.7 | 1.91 |

| 32571 | 105 | 160 | 35 | 205. 4 | 335.8 | 2.4 |

| 32571 | 110 | 170 | 38 | 245.7 | 403.4 | 3.02 |

| 32571 | 120 | 180 | 38 | 242.1 | 404.4 | 3.18 |

| 32026 | 130 | 200 | 45 | 333.7 | 567.1 | 4.94 |

| 32571 | 140 | 210 | 45 | 329.8 | 567.8 | 5.15 |

| 32030 | 150 | 225 | 48 | 367.6 | 635.8 | 6.25 |

| 32032 | 160 | 240 | 51 | 419.6 | 734.5 | 7.66 |

| 32207 | 35 | 72 | 24.25 | 70.6 | 89.5 | 0.426 |

| 32208 | 40 | 80 | 24.75 | 77.9 | 97.2 | 0.529 |

| 32209 | 45 | 85 | 24.75 | 80.7 | 104 | 0.587 |

| 32210 | 50 | 90 | 24.75 | 82.8 | 107.6 | 0.654 |

| 32211 | 55 | 100 | 26.75 | 108 | 142.3 | 0.881 |

| 32212 | 60 | 110 | 29.75 | 132.8 | 179.6 | 1.17 |

| 32213 | 65 | 120 | 32.75 | 160.9 | 221.7 | 1.58 |

| 32214 | 70 | 125 | 33.25 | 168.5 | 237.1 | 1.66 |

| 32215 | 75 | 130 | 33.25 | 170.3 | 242.1 | 1.76 |

| 32216 | 80 | 140 | 35.25 | 198.1 | 279 | 2.19 |

| 32217 | 85 | 150 | 38.5 | 226.7 | 324 | 2.7 |

| 32218 | 90 | 160 | 42.5 | 269.8 | 395.5 | 3.61 |

| 32219 | 95 | 170 | 45.5 | 302.5 | 448.4 | 4.34 |

| 32220 | 100 | 180 | 49 | 341 | 512 | 5.31 |

| 32221 | 105 | 190 | 53 | 342 | 517 | 6.37 |

| 32222 | 110 | 200 | 56 | 388 | 590 | 7.45 |

| 32224 | 120 | 215 | 61.5 | 420 | 610 | 9.04 |

| 32226 | 130 | 230 | 67.75 | 551.7 | 888.7 | 11.377 |

| 32228 | 140 | 250 | 71.75 | 643.7 | 1049.3 | 14.413 |

| 32307 | 35 | 80 | 32.75 | 99 | 118.3 | 0.766 |

| 32308 | 40 | 90 | 35.25 | 115.7 | 147.8 | 1 |

| 32309 | 45 | 100 | 38.25 | 145.3 | 189.4 | 1.41 |

| 32310 | 50 | 110 | 42.25 | 177.5 | 236.1 | 1.9 |

| 32311 | 55 | 120 | 45.5 | 203.1 | 271.4 | 2.33 |

| 32312 | 60 | 130 | 48.5 | 226.7 | 303 | 2.96 |

| 32313 | 65 | 140 | 51 | 259.6 | 349.8 | 3.53 |

| 32314 | 70 | 150 | 54 | 298.9 | 408.5 | 4.41 |

| 32315 | 75 | 160 | 58 | 347.4 | 483.1 | 5.27 |

| 32316 | 80 | 170 | 61.5 | 387.9 | 543.1 | 6.43 |

| 32317 | 85 | 180 | 63.5 | 421.8 | 592.8 | 7.31 |

| 32318 | 90 | 190 | 67.5 | 478.2 | 693.3 | 8.81 |

| 32319 | 95 | 200 | 71.5 | 516.1 | 737.7 | 10.1 |

| 32320 | 100 | 215 | 77.5 | 600.1 | 872.2 | 13 |

| 35717 | 35 | 72 | 18.25 | 54.2 | 63.5 | 0.333 |

| 35718 | 40 | 80 | 19.75 | 63 | 74 | 0.431 |

| 35719 | 45 | 85 | 20.75 | 67.9 | 83.6 | 0.474 |

| 35710 | 50 | 90 | 21.75 | 73.3 | 92.1 | 0.529 |

| 35711 | 55 | 100 | 22.75 | 90.8 | 113.7 | 0.713 |

| 35712 | 60 | 110 | 23.75 | 103.3 | 130 | 0.923 |

| 35713 | 65 | 120 | 24.75 | 120.6 | 152.6 | 1.58 |

| 35714 | 70 | 125 | 26.25 | 132.3 | 173.6 | 1.29 |

| 35715 | 75 | 130 | 27.25 | 138.4 | 185.4 | 1.4 |

| 35716 | 80 | 140 | 28.25 | 160.4 | 212.8 | 1.56 |

| 35717 | 85 | 150 | 30.5 | 177.6 | 236.8 | 2.06 |

| 35718 | 90 | 160 | 32.5 | 200.1 | 269.6 | 2.54 |

| 35719 | 95 | 170 | 34.5 | 226.6 | 309 | 3.04 |

| 35710 | 100 | 180 | 37 | 253.9 | 350.3 | 3.72 |

| 35711 | 105 | 190 | 39 | 285.3 | 398.6 | 4.38 |

| 35712 | 110 | 200 | 41 | 314.9 | 443.6 | 5.21 |

| 35714 | 120 | 215 | 43.5 | 337.4 | 483.3 | 6.2 |

| 35716 | 130 | 230 | 43.75 | 366 | 521.4 | 6.94 |

| 35718 | 140 | 250 | 45.75 | 409.2 | 584.7 | 8.73 |

| 35710 | 150 | 270 | 49 | 451.2 | 645.9 | 10.8 |

| 30306 | 30 | 72 | 20.75 | 59.6 | 60.1 | 0.389 |

| 30307 | 35 | 80 | 22.75 | 75.3 | 82.6 | 0.515 |

| 30308 | 40 | 90 | 25.25 | 80.5 | 90.2 | 0.761 |

| 30309 | 45 | 100 | 27.25 | 113 | 128 | 0.984 |

| 3571 | 50 | 110 | 29.25 | 145.3 | 189 | 1.26 |

| 3571 | 55 | 120 | 31.5 | 153.5 | 187.6 | 1.65 |

| 3571 | 60 | 130 | 33.5 | 171.4 | 210 | 1.96 |

| 3571 | 65 | 140 | 36 | 193 | 227 | 2.42 |

| 3571 | 70 | 150 | 38 | 219 | 271.7 | 3.04 |

| 3571 | 75 | 160 | 40 | 252.8 | 318.8 | 3.71 |

| 3 0571 | 80 | 170 | 42.5 | 278.8 | 352.5 | 4.27 |

| 3 0571 | 85 | 180 | 44.5 | 304.9 | 388.2 | 4.96 |

| 3 0571 | 90 | 190 | 46.5 | 342.1 | 440.9 | 5.8 |

| 3571 | 95 | 200 | 49.5 | 369 | 477.7 | 6.8 |

| 30320 | 100 | 215 | 51.5 | 406.4 | 526.4 | 8.22 |

| 33008 | 40 | 68 | 22 | 60.2 | 79.6 | 0.306 |

| 33009 | 45 | 75 | 24 | 72.6 | 100.4 | 0.398 |

| 33571 | 50 | 80 | 24 | 76.8 | 110.9 | 0.433 |

| 33011 | 55 | 90 | 27 | 94.9 | 144.7 | 0.651 |

| 33012 | 60 | 95 | 27 | 96.7 | 151.1 | 0.691 |

| 33013 | 65 | 100 | 27 | 98.1 | 157.7 | 0.732 |

| 33014 | 70 | 110 | 31 | 134.4 | 220.4 | 1.07 |

| 33015 | 75 | 115 | 31 | 133.1 | 221.2 | 1.12 |

| 33016 | 80 | 125 | 36 | 181.9 | 304.3 | 1.63 |

| 33017 | 85 | 130 | 36 | 180.4 | 305.5 | 1.69 |

| 33018 | 90 | 140 | 39 | 232.6 | 388.6 | 2.2 |

| 33019 | 95 | 145 | 39 | 231 | 389.9 | 2.26 |

| 33571 | 100 | 150 | 39 | 229.5 | 391.2 | 2.33 |

| 33571 | 105 | 160 | 43 | 257.4 | 437.4 | 2.97 |

| 33571 | 110 | 170 | 47 | 288.7 | 502.7 | 3.74 |

| 33571 | 120 | 180 | 48 | 298.2 | 535.1 | 4.07 |

| 33026 | 130 | 200 | 55 | 400.6 | 727.4 | 6.14 |

| 33571 | 140 | 210 | 56 | 407 | 755.5 | 6.57 |

| 33030 | 150 | 225 | 59 | 461.2 | 873.8 | 7.98 |

| 33108 | 40 | 75 | 26 | 84.7 | 110.3 | 0.496 |

| 33109 | 45 | 80 | 26 | 87.1 | 117.2 | 0.535 |

| 33110 | 50 | 85 | 26 | 89.3 | 124.1 | 0.572 |

| 33111 | 55 | 95 | 30 | 114.5 | 164.8 | 0.483 |

| 33112 | 60 | 100 | 30 | 117.1 | 173.2 | 0.895 |

| 33113 | 65 | 110 | 34 | 142.8 | 220.4 | 1.3 |

| 33114 | 70 | 120 | 37 | 172.1 | 267 | 1.7 |

| 33115 | 75 | 125 | 37 | 176.1 | 279.6 | 1.78 |

| 33116 | 80 | 130 | 37 | 179.6 | 292.3 | 1.87 |

| 33117 | 85 | 140 | 41 | 215.7 | 354.2 | 2.43 |

| 33118 | 90 | 150 | 45 | 252.1 | 414.7 | 3.13 |

| 33119 | 95 | 160 | 49 | 298.9 | 498.2 | 3.94 |

| 33120 | 100 | 165 | 52 | 309.4 | 529.2 | 4.31 |

| 33121 | 105 | 175 | 56 | 351.8 | 607.8 | 5.29 |

| 33122 | 110 | 180 | 56 | 373.2 | 639.1 | 5.5 |

| 33124 | 120 | 200 | 62 | 448.2 | 779.1 | 7.68 |

| 33207 | 35 | 72 | 28 | 82.6 | 101.7 | 0.515 |

| 33208 | 40 | 80 | 32 | 105.8 | 135.5 | 0.715 |

| 33209 | 45 | 85 | 32 | 109.5 | 145.1 | 0.771 |

| 33210 | 50 | 90 | 32 | 112.9 | 154.6 | 0.825 |

| 33211 | 55 | 100 | 35 | 35 | 196.7 | 1.15 |

| 33212 | 60 | 110 | 38 | 38 | 231.4 | 1.51 |

| 33213 | 65 | 120 | 41 | 41 | 281.6 | 1.99 |

| 33214 | 70 | 125 | 41 | 41 | 298.3 | 2.1 |

| 33215 | 75 | 130 | 41 | 41 | 299.7 | 2.17 |

| 33216 | 80 | 140 | 46 | 46 | 361.8 | 2.83 |

| 33217 | 85 | 150 | 49 | 49 | 415.7 | 3.52 |

| 33218 | 90 | 160 | 55 | 55 | 499.7 | 4.55 |

| 33219 | 95 | 170 | 58 | 58 | 568.4 | 5.48 |

| 33220 | 100 | 180 | 63 | 63 | 666.2 | 6.71 |

| 33221 | 105 | 190 | 68 | 68 | 770.5 | 8.12 |

| 32909 | 45 | 68 | 15 | 32 | 48.4 | 0.18 |

| 32910 | 50 | 72 | 15 | 36.9 | 56.1 | 0.181 |

| 32911 | 55 | 80 | 17 | 41.5 | 66.7 | 0.262 |

| 32912 | 60 | 85 | 17 | 46.1 | 73.1 | 0.279 |

| 32913 | 65 | 90 | 17 | 45.4 | 73.2 | 0.295 |

| 32914 | 70 | 100 | 20 | 70.8 | 114.7 | 0.471 |

| 32915 | 75 | 105 | 20 | 78.2 | 124.7 | 0.49 |

| 32916 | 80 | 110 | 20 | 79.3 | 129 | 0.514 |

| 32917 | 85 | 120 | 23 | 96.9 | 164.1 | 0.767 |

| 32918 | 90 | 125 | 23 | 95.8 | 164.5 | 0.798 |

| 32919 | 95 | 130 | 23 | 97.1 | 169.8 | 0.931 |

| 32920 | 100 | 140 | 25 | 126.6 | 218.4 | 1.12 |

| 32921 | 105 | 145 | 25 | 128 | 255.6 | 1.16 |

| 32922 | 110 | 150 | 25 | 129.7 | 232.6 | 1.2 |

| 32924 | 120 | 165 | 29 | 171.9 | 317.3 | 1.78 |

| 32926 | 130 | 180 | 32 | 206 | 380.6 | 2.34 |

| 32928 | 140 | 190 | 32 | 207.2 | 392.4 | 2.47 |

| 32930 | 150 | 210 | 38 | 261 | 510.4 | 3.87 |

| 32932 | 160 | 220 | 38 | 262.8 | 525.4 | 4.07 |

| 32934 | 170 | 230 | 38 | 280.1 | 561.5 | 4.33 |

ZheJiang REET BEARING.CO.,LTD is a professional bearing manufacturer and exporter.

We have a wealth of technical.All producing processes are finished in our manufactory. As an ISO9001:2000 certified manufacturer,we will solve various problems in application and use of our bearings.

Our company is an authorized distributor of FAG, INA, CZPT and other world brand bearings.Our company has the right to self-export bearings and launches its own brand RTB.

Our bearing had been exported to more than 20 countries worldwide and are warmly welcomed.

We’re looking forward to your order.

FAQ

1.Is the company a production factory or a trading company?

ZheJiang REET BEARING CO.,LTD is a manufacturing enterprise focusing on bearings and integrating research, production and sales.

2.How many the MOQ of your company?

Depending on the size of the bearing, the MOQ is variable, if you are interested, you can contact me for a quote.

3.Does the company accept OEM or customized bearings?

In addition to standard products, we also supply non-standard and modified standard products for special application. Meanwhile, we provide OEM service.

4.Can the company provide free samples?

We can provide samples for free. You only need to provide shipping.

5.What are the company’s delivery terms?

We can accept EXW,FOB,CFR,CIF,etc. You can choose the 1 which is the most convenient cost effective for you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rated Dynamic Load: | 643.7 |

|---|---|

| Rated Static Load: | 1049.3 |

| Weight: | 14.413 |

| Rolling Body: | Roller Bearings |

| The Number of Rows: | Single |

| Material: | Bearing Steel |

| Samples: |

US$ 6/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Role of Sliding Bearings in Vibration Dampening and Shock Absorption Applications

Sliding bearings are essential components in applications where vibration dampening and shock absorption are critical. Here’s how they fulfill this role:

Vibration Dampening:

In various industrial processes and equipment, vibrations can lead to reduced performance, increased wear and tear, and even structural damage. Sliding bearings help dampen vibrations by providing a cushioning effect between moving components. The design of sliding bearings allows them to absorb and dissipate vibrations, preventing them from propagating throughout the machinery.

Shock Absorption:

Heavy machinery and equipment often experience sudden impacts or shocks due to sudden loads or external forces. Sliding bearings with their ability to absorb shocks and impacts help protect machinery from damage. They act as buffers that absorb and distribute the energy generated by these shocks, preventing it from causing harm to other components or the machinery structure.

Isolation of Vibrations:

Sliding bearings can be strategically placed in machinery to isolate specific components or sections from vibrations. This isolation helps maintain the stability and accuracy of delicate components that might be sensitive to vibrations, such as precision instruments or measurement devices.

Enhanced Comfort:

In applications involving human interaction, such as vehicles or industrial tools, sliding bearings contribute to user comfort. By reducing vibrations and shocks transmitted to the operator or occupants, sliding bearings improve the overall user experience and reduce operator fatigue.

Prevention of Resonance:

Resonance is a phenomenon where vibrations can be amplified due to the natural frequencies of the components. Sliding bearings help prevent resonance by providing damping properties that counteract the amplification effect. This is crucial in applications where precise control and stability are required.

In conclusion, sliding bearings play a vital role in applications requiring vibration dampening and shock absorption. Their ability to dampen vibrations, absorb shocks, isolate vibrations, enhance comfort, and prevent resonance contributes to the efficient and reliable operation of machinery and equipment in various industries.

Maintenance Practices to Extend the Lifespan of Sliding Bearings

Proper maintenance is essential for maximizing the lifespan of sliding bearings and ensuring optimal performance. Here are specific practices that can help extend the life of sliding bearings:

Regular Lubrication: Adequate lubrication is crucial for minimizing friction and wear between sliding surfaces. Follow manufacturer recommendations for lubrication intervals and use the appropriate lubricants for the operating conditions.

Clean Environment: Keep the surrounding environment clean and free from dust, dirt, and contaminants. Regularly clean the machinery or equipment to prevent debris from entering the bearing area.

Seal Integrity: Ensure that bearing seals are in good condition to prevent contaminants from entering and lubricant from escaping. Replace damaged seals promptly to maintain proper protection.

Alignment and Mounting: Proper alignment and mounting of sliding bearings are critical to distribute loads evenly and prevent excessive wear. Follow manufacturer guidelines for installation procedures and torque specifications.

Regular Inspections: Schedule routine inspections to detect early signs of wear, damage, or misalignment. Visual inspections, temperature checks, and vibration analysis can help identify issues before they escalate.

Maintenance Records: Maintain detailed records of maintenance activities, including lubrication schedules, inspections, and replacements. This information can help track the condition of sliding bearings and plan maintenance tasks effectively.

Temperature Management: Control operating temperatures within recommended limits. Excessive heat can degrade lubricants and accelerate wear, while extreme cold can affect bearing performance.

Load Management: Avoid subjecting sliding bearings to loads beyond their specified capacities. Overloading can lead to premature wear and damage.

Training and Education: Ensure that personnel responsible for maintenance are adequately trained in proper procedures. Knowledgeable staff can perform maintenance tasks accurately and identify potential issues.

Timely Replacement: When wear or damage is detected that exceeds acceptable limits, replace sliding bearings promptly to prevent further damage to the machinery or equipment.

By implementing these maintenance practices, you can significantly extend the lifespan of sliding bearings, reduce downtime, and optimize the performance of machinery and equipment.

Considerations for Selecting Sliding Bearings

When choosing a sliding bearing for a specific application, several key factors should be taken into consideration:

- Load Capacity: Determine the maximum load the bearing will need to support. This includes both radial and axial loads, as well as any dynamic or static loads.

- Operating Conditions: Consider the operating environment, including temperature, humidity, and exposure to chemicals or contaminants. Different materials and coatings may be required for harsh conditions.

- Lubrication: Choose the appropriate lubrication method based on the application. Consider factors such as the frequency of lubrication, the availability of lubrication points, and the compatibility of lubricants with the bearing material.

- Speed and Motion: Evaluate the speed and type of motion the bearing will experience. Higher speeds may require special considerations for heat dissipation and lubrication.

- Alignment and Misalignment: Determine if the bearing will need to accommodate misalignment between the shaft and the bearing housing. Some applications may require self-aligning or spherical bearings.

- Wear Resistance: Choose a bearing material that offers good wear resistance to prevent premature wear and extend the bearing’s lifespan.

- Noise and Vibration: Consider the impact of noise and vibration on the application. Bearings with proper damping properties can help reduce noise and vibration levels.

- Maintenance Requirements: Assess the ease of maintenance, including lubrication intervals, accessibility of lubrication points, and the need for regular inspections.

- Cost and Availability: Compare the cost of the bearing with its expected performance and lifespan. Also, ensure that the chosen bearing type and size are readily available.

- Application-Specific Considerations: Some applications may have unique requirements, such as corrosion resistance, electrical insulation, or compatibility with food-grade standards.

By carefully considering these factors, you can select a sliding bearing that meets the specific needs of your application, ensuring reliable performance and longevity.

editor by CX 2024-05-08

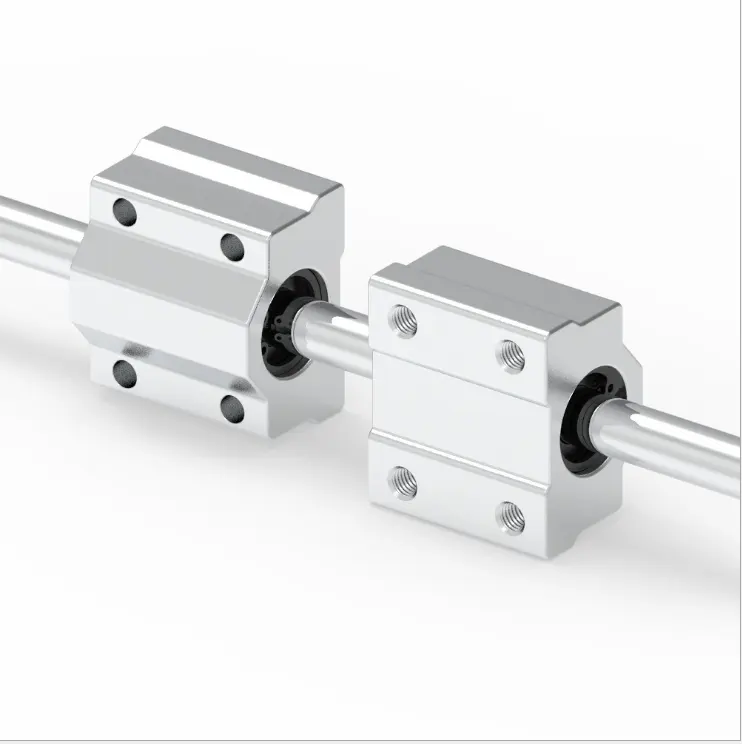

China best 7x22x9 mm Polyurethane Soft Rubber Wheel Nylon Coated Ball Bearing With Stud/ Sliding Roller For Windows drive shaft bearing

Product Description

Product Description

Polyurethane Soft Rubber Wheel

PU Coated Ball Bearings With Stainless Steel Stud, we can offe M3 M4 M5 M6 M8 and Non-standard Size.

Product Parameters

Technical specification:

Material: Polyurethane Coated with Stainless Steel Stud

Packaging & Shipping

Our Advantages

1. We have over 10 years’ experience.

2. OEM or Non-Standard Bearings: Any requirement for Non-standard bearings is easily fulfilled by us due to our vast knowledge and links in the industry.

3. After Sales Service and Technical Assistance: Our company provides after-sales service and technical assistance as per the customer’s requirements and needs.

4. Quick Delivery: Our company provides just-in-time delivery with our streamlined supply chain.

5.We attend promptly to any customer questions. We believe that if our customers are satisfied then it proves our worth. Our customers are always given quick support.

Please contact us immediately if you have any questions.

Related Products

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Non-Aligning Bearing |

|---|---|

| Separated: | Unseparated |

| Rows Number: | Single |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Improvement of Heavy Machinery Operation with Sliding Bearings

Sliding bearings play a crucial role in enhancing the operation of heavy machinery, such as mining equipment. Here’s how they contribute:

Reduced Friction and Wear:

Sliding bearings are designed to minimize friction between moving parts. In heavy machinery, where components are subjected to substantial loads and harsh conditions, reducing friction is essential to prevent premature wear and damage. Sliding bearings help distribute loads evenly and provide a smooth surface for components to slide against, reducing the risk of friction-induced failures.

Increased Durability:

The robust construction and materials used in sliding bearings make them well-suited for heavy machinery applications. They can withstand the heavy loads, impacts, and vibrations commonly encountered in mining equipment. Their durability contributes to the overall reliability and longevity of the machinery.

Improved Efficiency:

Efficiency is critical in heavy machinery to maximize productivity while minimizing energy consumption. Sliding bearings contribute to improved efficiency by reducing energy losses due to friction. With lower friction, machinery components can move more freely, requiring less energy to overcome resistance.

Resistance to Contaminants:

Mining environments are often filled with dust, dirt, and debris that can infiltrate machinery components. Sliding bearings are designed to operate effectively even in contaminated conditions. Their design and materials help prevent the intrusion of contaminants, reducing the risk of premature wear and component failure.

Enhanced Load Distribution:

Heavy machinery, especially in mining, experiences dynamic and uneven loads. Sliding bearings help distribute these loads evenly across surfaces, preventing localized stress concentrations. This load distribution contributes to the machinery’s overall structural integrity and minimizes the risk of catastrophic failures.

In conclusion, sliding bearings are integral to the efficient and reliable operation of heavy machinery in industries like mining. Their ability to reduce friction, enhance durability, improve efficiency, resist contaminants, and distribute loads makes them invaluable components for ensuring the smooth functioning of mining equipment.

Enhancing Efficiency of Marine Propulsion Systems with Sliding Bearings

Sliding bearings play a crucial role in enhancing the efficiency of marine propulsion systems and various ship components. Here’s how sliding bearings contribute to the efficiency of maritime applications:

Reduced Friction: Sliding bearings are designed to minimize friction between moving parts. In marine propulsion systems, such as propeller shafts and stern tubes, reduced friction results in less energy loss and improved fuel efficiency.

Smooth Operation: Sliding bearings provide smooth and controlled movement of rotating or linear components. In marine applications, this smooth operation translates to improved maneuverability, reduced vibrations, and enhanced overall performance.

Load Distribution: Sliding bearings distribute loads evenly across bearing surfaces. This even distribution helps prevent localized wear and reduces the risk of premature failure, ensuring reliable operation of ship components.

Resistance to Harsh Environments: Marine environments expose equipment to corrosive saltwater, extreme temperatures, and harsh weather conditions. Sliding bearings are often designed with materials and coatings that offer corrosion resistance and durability, ensuring longevity even in challenging maritime settings.

Enhanced Lubrication: Lubrication is vital for reducing wear and friction in sliding bearings. Many marine applications use advanced lubrication systems that optimize the distribution of lubricants, further reducing friction and improving efficiency.

Space Efficiency: Sliding bearings are compact and require minimal space, making them suitable for marine systems where space is limited. This efficient use of space is particularly important in ship design and layout.

Customization for Specific Needs: Sliding bearings can be tailored to meet the specific requirements of different ship components. This customization ensures that bearings are optimized for their intended functions, further contributing to efficiency.

Reduced Maintenance: Properly designed sliding bearings require less maintenance compared to some other types of bearings. This reduced maintenance need translates to less downtime and increased operational efficiency for marine vessels.

Optimized Performance: Overall, the efficient and reliable performance of sliding bearings in marine propulsion systems and ship components leads to improved energy efficiency, reduced operational costs, and extended service life of the equipment.

By incorporating sliding bearings into marine applications, shipbuilders and operators can achieve enhanced efficiency, reliability, and sustainability in their operations.

Design Principles and Functions of Sliding Bearings

Sliding bearings, also known as plain bearings or journal bearings, operate on the principle of providing a low-friction interface between two moving surfaces. The design of sliding bearings is based on creating a film of lubrication between the bearing surface and the shaft or journal it supports. This film of lubrication separates the two surfaces and minimizes direct metal-to-metal contact, reducing friction and wear.

The main components and design principles of sliding bearings include:

- Bearing Material: Sliding bearings are typically made from materials with good wear resistance and self-lubricating properties, such as bronze, brass, or various polymers. These materials help reduce friction and prevent excessive wear.

- Lubrication: Lubrication is crucial for the proper functioning of sliding bearings. It can be provided by an external lubricant, solid lubricants embedded in the bearing material, or a combination of both. The lubrication forms a protective layer that reduces direct contact and minimizes friction.

- Clearance: Sliding bearings are designed with a specific clearance between the bearing and the shaft to accommodate the lubricating film and allow for proper movement. This clearance prevents seizing and binding of the bearing.

- Load Distribution: The design of sliding bearings ensures that the load is distributed over a larger surface area to prevent excessive stress on any single point. This feature is essential for handling heavy loads in industrial applications.

- Alignment and Misalignment: Sliding bearings can tolerate small misalignments between the bearing and the shaft. This flexibility allows them to accommodate minor shifts caused by thermal expansion, vibration, or other factors.

- Heat Dissipation: Sliding bearings can generate frictional heat during operation. Proper design includes features to facilitate heat dissipation and prevent overheating that could lead to premature wear.

- Application-Specific Design: The design of sliding bearings can vary based on the specific application requirements, including load capacity, speed, operating temperature, and environmental conditions.

The functions of sliding bearings include providing support to rotating or sliding shafts, reducing friction, absorbing and distributing loads, allowing for misalignment, and offering smooth movement even in dirty or contaminated environments. Sliding bearings are commonly used in various industrial machinery and equipment, including engines, pumps, conveyors, and manufacturing equipment.

Overall, the design principles and functions of sliding bearings make them suitable for applications where low friction, durability, load-bearing capacity, and adaptability to varying conditions are essential.

editor by CX 2024-02-17

China Original All Sizes Taper Roller Bearing H91384910 For hydropower and water conservancy drive shaft bearing

Sort: Roller

Construction: Taper

Relevant Industries: Equipment Mend Outlets, Food & Beverage Manufacturing unit, Home Use, Retail, Building works , Strength & Mining, Promoting Business

Model Amount: H913849/10

Precision Ranking: P6

Seals Type: Open up

Quantity of Row: Single row

Software: engineering, railway, Agricultural Machinery Pto Cardan Shaft for Electrical power Transmission

High quality: Orignal

Supply time: 3-7 Operating Times

Guarantee: 1 Yr

Package deal: Origina Package deal

Certification: ISO9001

Approach: Casting +Machining(if Require)+floor Treatment

Software automobile: Rapidly GEARBOX

Support: 24 Hours Client Provider

MOQ: 1 Piece

Packaging Information: picket bins ,carton packing containers or as you needed

Port: HangZhou

Taper Roller Bearing, One Row, Tapered Roller Bearings usually appear in 2 elements – the cone (consisting of the interior ring and roller cage assembly) and the cup (outer ring). These 2 elements can be mounted independently.Tapered Roller Bearings are especially suited to the accommodation of merged radial and axial loads

| item | H913849-H913810 |

| inside diameter | 69.850mm |

| outside diameter | 146.050mm |

| width | 36.512mm |

| Stock | 520pcs |

| 35712 | 15 | 35 | 12 | 0.05 |

| 35713 | 17 | 40 | 13.5 | 0.074 |

| 35714 | 20 | 47 | 15.5 | 0.twelve |

| 35715 | 25 | 52 | 16.five | 0.fifteen |

| 35716 | 30 | 62 | 17.5 | 0.232 |

| 35717 | 35 | 72 | 18.5 | 0.32 |

| 35718 | 40 | 80 | 20 | 0.4 |

| 35719 | 45 | 85 | 21 | 0.474 |

| 35710 | 50 | 90 | 22 | 0.522 |

| 35711 | 55 | 100 | 23 | 0.709 |

| 35712 | 60 | 110 | 24 | 0.901 |

| 35713 | 65 | 120 | 25 | 1.1 |

| 35714 | 70 | 125 | 26.five | 1.27 |

Industrial applications of casing

For rotating and sliding parts, bushings are an important part of the machine. Due to their anti-friction properties and load-carrying capacity, they are an important part of many different industrial processes. Bushings play a vital role in industries such as construction, mining, hydropower, agriculture, transportation, food processing and material handling. To learn more about the benefits of bushings, read on. You’ll be amazed how much they can help your business!

type

When comparing enclosure types, consider the material and how it will be used. Oilite bushings are made of porous material that draws lubricant into the liner and releases it when pressure is applied. These are manufactured using a sintered or powered metal process. Copper and tin are the most commonly used materials for making copper bushings, but there are other types of metal bushings as well.

Another popular type is the plain bearing. This type reduces friction between the rotating shaft and the stationary support element. This type provides support and load bearing while relying on soft metal or plastic for lubrication. Journal bearings are used to support the linear motion of the engine crankshaft in large turbines. They are usually babbitt or hydrodynamic with a liquid film lubricant between the two halves.

The oil-impregnated paper sleeve is made of high-quality kraft insulating paper. These bushings contain two layers of capacitor grading, with the innermost layer electrically connected to the mounting flange. These are mature processes and are widely used in different voltage levels. CZPT Electric (Group) Co., Ltd. provides UHV DC and AC oil-impregnated paper wall bushings for environmental control rooms.

Electrical bushings are used to transmit electricity. These can be transformers, circuit breakers, shunt reactors and power capacitors. The bushing can be built into the bushing or through the bushing. The conductors must be able to carry the rated current without overheating the adjacent insulation. A typical bushing design has a conductor made of copper or aluminum with insulation on all other sides. If the bushing is used in a circuit, the insulation needs to be high enough to prevent any leakage paths.

Voltage and current ratings of electrical bushings. Solid type electrical bushings typically have a center conductor and a porcelain or epoxy insulator. These bushings are used in small distribution transformers and large generator step-up transformers. Their test voltage is typically around 70 kV. Subsequent applications of this bushing may require a lower halfway release limit. However, this is a common type for many other applications.

application

Various industrial applications involve the use of casing. It is an excellent mechanical and chemical material with a wide range of properties. These compounds are also packaged according to national and international standards. Therefore, bushings are used in many different types of machines and equipment. This article will focus on the main industrial applications of casing. This article will also explain what a casing is and what it can do. For more information, click here. Casing application

Among other uses, bushing assemblies are used in aircraft and machinery. For example, a fuel tank of an aircraft may include baffle isolator 40 . The bushing assembly 16 serves as an interface to the fuel tank, allowing electrical current to flow. It can also be used to isolate one component from another. In some cases, bushing assemblies are used to provide a tight fit and reduce electrical resistance, which is important in circuits.

The benefits of casing go beyond reducing energy transmission. They reduce lubrication costs. If two metal parts are in direct contact, lubrication is required. Thus, the bushing reduces the need for lubrication. They also allow parts of the car to move freely. For example, rubber bushings may begin to deteriorate due to high internal temperatures or cold weather. Also, oil can affect their performance.

For example, bushing CTs in oil and gas circuit breakers are used as window current transformers. It consists of a toroidal core and secondary windings. The center conductor of the bushing acts as the single-turn primary of the BCT. By tapping the secondary winding, the ratio between primary and secondary can be changed. This information can be found on the asset nameplate.

Among other uses, bushings are used in diagnostic equipment. These components require precise positioning. Fortunately, air sleeves are perfect for this purpose. Their frictionless operation eliminates the possibility of misalignment. In addition, products based on porous media help minimize noise. A casing manufacturer can advise you on the best product for your equipment. Therefore, if you are looking for replacement bushings for your existing equipment, please feel free to contact Daikin.

Material

Dry ferrule cores were selected for study and examined under an Olympus polarizing microscope (BX51-P). Core slices showing layers of aluminum foil with a distance of approximately 2 cm between adjacent capacitor screens. The aluminum foil surface has a multi-layered structure with undulations due to shrinkage and crepe. Differences between the two types of foils are also revealed.

A typical metal bushing material consists of a high-strength metal backing and a solid lubricant. These materials have higher load-carrying capacity and low friction during operation. Additionally, they are precision machined to tight tolerances. They also offer better thermal conductivity and better fatigue resistance. The accuracy of the metal bushing is improved due to the re-machining process that takes place after the bearing is assembled. Additionally, metal bushing materials are more resistant to wear than plastic bushing materials.

Plastic bushings are relatively inexpensive and readily available off the shelf. Also, the price of custom plastic bushings is relatively low. However, they are not recommended for heavy duty applications. Plastics degrade under high loads and can damage mating parts. Also, if the plastic bushings are not manufactured accurately, they can become misaligned. These are just some of the reasons for choosing metal bushings over plastic.

A mechanically bonded bushing 40 is placed over the stabilizer bar and compressed into the outer sleeve/bracket assembly. The outer metal member includes slotted holes that compensate for the tolerance stacking between the first and second bushing assemblies. Pre-assembly allows the assembly plant to receive a complete assembly ready for vehicle assembly, rather than sub-assembly at the vehicle manufacturing plant.

cost

Control arm bushings are a major component of modern vehicle suspension systems. Damaged bushings can negatively affect the handling and performance of your car. Replacing bushings on a car can cost $200 to $500. While that’s pretty cheap for a handful of control bushings, replacing the entire suspension system could set you back over $1,200. Thankfully, if you want to repair or replace the bushing yourself, you can do it yourself for a fraction of the cost.

If you decide to replace the control arm bushing yourself, it’s best to shop around for the best price. Many auto parts stores offer cheaper bushings that you don’t have to spend a fortune on. Even if you don’t drive for years, rubber can degrade and create cracks in the material. These cracks can be as deep as three-eighths of an inch. This makes it dangerous to drive a car with damaged control arm bushings.

Hiring a mechanic might be a good idea if you don’t like doing the work yourself. You can save money and time by repairing the control arm yourself, but you may have to hire a mechanic to do the job. Replacing the front sway bar bushing alone can cost between $450 and $900. While these components are relatively inexpensive, you can replace them for a better-handling car.

In some cases, sizing the bushings is a more economical option, but if you want to replace your entire suspension system, it’s better to buy a brand new lower limit. You can even save labor by buying a replacement part fork with a good lower portion. In addition to improving your car’s handling and ride, new bushings will add to your car’s overall value. If you are not sure which parts you need, ask your mechanic for a quote.

While the cost of replacing control arm bushings is relatively low, it’s a good idea to compare quotes from multiple mechanics. By getting multiple quotes for the same repair, you can save as much as $50 to $100 on the total cost of your car. In addition to labor costs, parts and labor can vary, so shop around to find the mechanic best suited for your car. There’s no reason to settle for sub-par service when you can save $50 or more!

editor by czh 2023-02-19

China High quality NUP 306 Cylindrical roller bearing NU NN NUP NJ 306 305 drive shaft bearing

Variety: Roller

Composition: cylindrical

Applicable Industries: Hotels, Garment Outlets, Creating Material Retailers, Production Plant, Machinery Restore Shops, Foods & Beverage Manufacturing unit, Farms, Restaurant, Residence Use, Retail, Foods Store, Printing Shops, Development works , Power & Mining, Meals & Beverage Shops, Advertising Company

Model Number: nup 306

Precision Rating: ABEC3 ABEC5 ABEC7 ABEC9

Seals Type: Open

Number of Row: Solitary row

Item: nup 306 cylindrical roller bearing

Cage: nylon, steel, Substantial Efficiency 32206JR 32006 CZPT Taper Roller Bearing dimension 30X55X16MM brass

Clearance: C1,C2,C3

Vibrating Amount: Z1V1 Z2V2 Z3V3

Main Market: Jap Europe, Southeast Asia, South America

Services: OEM is acceptable

Bearing content: steel bearings, carbon bearings, stainless bearings

Certificates: ISO9001,

samples/inventory: accessible

Packing particulars: according to client’s specifications

Packaging Particulars: NUP 306 Cylindrical roller bearing NU NN NUP NJ 306 305Package specifics 1. Neutral Bundle: Plastic Bag + Carton + Pallet 2. Industrial Bundle: Plastic Bag + Box + Carton + Pallet 3. As the clients’ need.

Welcome HangZhou BAQI

Product PARAMETERS

| Model amount | NUP 306 |

| Dimension(mm) | 30X72X19 |

| Weigh(kg) | .38 |

| Greese/Oil | As you necessity,such as SRL ,PS2,AIVania R12 and so on |

| Series | Cylindrical Roller Bearing |

| Ring Material | Chrome Metal,Carbon steel,bearing metal |

| Top quality common | ISO 9001:2000 standard |

| Precision | p0,p6,p5, 23228 CCW33 spherical roller bearing 23228CC 23228CCW33 p4 |

| Steel pressed cage | Bending claw kind or rivet type |

| Supply Day | Normally all set products and stock within 7 times |

| Payment Time period | T/T, L/C,Western Union |

| Application | Home appliances,low noise and substantial pace electric powered motors,automotive factors,pumps |

| Support | OEM ODM |

| Bundle | industrial deal+paper box/wood box one deal+paper box/wood box |

| Particulars | we have complete procedure for the generation and high quality assurance to make positive our product 1.Assembly 2,Windage take a look at 3,Cleansing 4,Rotary examination 5,Greasing and gland 6,Sounds inspection 7,Rust avoidance 9,Product packaging |

Related Goods

Packaging + Shipping and delivery NUP 306 Cylindrical roller bearing NU NN NUP NJ 306 305 have various kinds of packing strategies.

About Us

HangZhou BAQI BEARING CO.,LTD

Our Price Information is “Quality Is Our Lifestyle”

HangZhou Baqi bearing Co., Ltd is a producer of bearings, High Top quality Gbm7508 2.5N.M Manufacturing unit Manufactured Tiny Dimensions 75Mm Hollow Shaft Actuator Outer Runner Bldc Gimbal Motor more than fifteen a long time expertise, and with three hundred experienced workers, 90% of our generation gear is imported from Japan and Germany to offer our customers the very best competitive advantage Goods.

Our manufacturer ” BQB”, we are 1 of the 1st mover of bearing enterprise in China. our main competencies is “ball bearing and roller bearing”

Certificate

We are authorization distributor of well-known manufacturer SKF, FAG, NSK, NTN, KOYO, NACHI, FYH bearings and many others.

Software

NUP 306 Cylindrical roller bearing NU NN NUP NJ 306 305 are broadly employed in industrial fields

Consumers Opinions

FAQ

Q Are you buying and selling company or producer?A We are factory. HangZhou Baqi Bearing Co.,Ltd integrates creation, trade, expense and sales.Q Do you accept ODM& China supplier 32036x Bearing 32306 Machinery 32306 Bearing OEM orders?a Of course. We supply ODM&OEMservices to around the world clients. We are CZPT to personalize housings in different designs and dimensions in distinct brands. We also personalize Q Do you like to serve the customer only with tiny orders?A We enjoy to expand up together with all our clients whatever massive or little. Q Could you tell me the shipping and delivery time of your doodsA If inventory,in 7days or foundation on your get amount

Advantages and disadvantages of different types of bushings

Bushings are a simple but essential part of machinery with sliding or rotating shaft assemblies. This type of bearing is used in a wide variety of industries because its high load-carrying capacity and excellent anti-friction properties make it a necessity for construction, mining, hydropower, transportation and agricultural machinery. In addition to these applications, bushings also play a vital role in material handling and food processing. This article explores the various types of bushings available.

air casing

The air bushing forms a frictionless cylinder that applies the load to the rotating object. Bushings are used to measure torque and provide self-centering force in applications where linear motion is critical. The following are load equations that can be used to select the appropriate air sleeve for your application. To learn more about these air sleeves, read on. This article discusses the benefits and uses of air bushings in linear motion.

Bushings have many advantages over bearings. They are not prone to wear and corrosion. Unlike bearings, they can easily bypass conversion and inspection periods. Their high-quality design guarantees reliable machine performance, yet they are inexpensive and easy to replace. In many industries, air compressors are essential for sports. The air bushing eliminates friction, allowing the compressor to work more efficiently. They can also help eliminate the need for frictionless bearings and improve the overall efficiency of the machine.

Another type of air bearing is the cylindrical bushing. These are used for linear and aerostatic motion. Their low friction properties allow them to support radial loads without wearing out or damaging components. They are usually used for normal sized shafts. Air bushings have several components that can be used with other types of air bearings. Cylindrical air bearings have four o-ring grooves that allow them to be inserted into the structure. They are often used with other types of air bearings for smoother motion.

rubber bushing

If you’re looking to buy a new suspension system, you may be wondering if rubber or polyurethane is the right choice. Rubber is less expensive, but not without its drawbacks. Polyurethane is more durable and offers better handling and suspension. Rubber bushings also reduce road feel, while polyurethane isolates the driver from the road. Both materials will help you improve handling and alignment, but each has advantages and disadvantages.

Typically, rubber bushings are cylindrical components with metal inner and outer surfaces. These metals can be stainless steel, mild steel or aluminum. They are usually stress relieved and prestressed for maximum durability. They are designed to meet the exact specifications of a specific application. For example, shock-absorbing rubber bushings are cushioning pads made of polyurethane that absorb road bumps and noise.

Unlike polyurethane, rubber suspension bushings have a shorter lifespan than polyurethane. This is because rubber is more susceptible to damage from UV rays, road chemicals and oils. The rubber also stretches and warps due to the pressure of the road. The rubber bushing also squeaks, which can be cause for concern. But if the noise persists for a long time, it may be a sign that your vehicle needs a new suspension system.

The main reason why cars use rubber bushings is for shock absorption. During machine use, vibration and noise caused by the movement of parts can cause serious damage. To prevent this, rubber bushings act as shock absorbers and damping agents. Rubber bushings are an excellent choice for automakers, but they are also used in a variety of industrial settings.

Polyurethane bushing

If you want to make your vehicle handle better, polyurethane bushings may be the answer. They come in different shapes and sizes and can improve a wide range of areas. This article will explore the advantages and disadvantages of polyurethane bushings and their potential place in your car. However, before you decide to upgrade your suspension, you should understand the various advantages and disadvantages of polyurethane bushings.

The main difference between a polyurethane bushing and a rubber bushing is how the bushing rides on the suspension arm. Polyurethane bushings do not have faces that slide against each other like rubber bushings. This means they allow for more rotation and flexion, as well as consistent alignment of the control arms. Polyurethane bushings require lubrication, but only need to be lubricated every five years, much longer than equivalent rubber bushings.

Another difference between polyurethane and rubber bushings is hardness. The former has the least elasticity and is generally the most suitable for street use. While rubber bushings provide the best NVH quality, they are also notorious for changing suspension geometry. Rubber is known to be an excellent choice for street use, but polyurethane has a lifespan that far outlasts rubber.

bronze bushing

There are two main types of bronze bushings, sintered and cast. The latter require additional lubrication and are typically used in applications where powder metal products cannot be secured. The former is cheaper than the latter, but the process is more expensive. Bronze bushings can be used in environments where the material will be exposed to high temperature and vibration. For these reasons, the production process is relatively slow and expensive.

The strength of bronze is the main reason why they are so popular. Brass is a softer metal that deforms and corrodes easily. The bronze casing can withstand continuous immersion in water and can last for hundreds of years with little or no maintenance. However, it is important to note that this metal is not resistant to aggressive chemicals and requires regular maintenance to keep it in good condition.

Bronze bushings offer many advantages, including durability and aesthetics. Bronze bushings are available in a variety of sizes and can be ordered in imperial and metric sizes. They can be built to your specifications and are very durable. You can even custom order them if you want. And because they can be customized, they are an excellent choice for high-end applications. The quality of the bronze bushings is second to none.

Plastic bushing

Engineered composite plastic bushings have been shown to last longer than bronze bushings and have also been found to reduce maintenance costs by up to 40%. Plastic bushings have become the first choice for thousands of applications, including medical equipment, food processing machinery, pumps, and more. Bronze bushings are oil-impregnated, but their performance is limited by their inherent weaknesses: oil-impregnated bronze tends to develop high levels of capillary action and requires rotational motion to maintain an intact oil film. Low speed and intermittent use of bronze bushings can also hinder the ability of the lubricant to provide adequate lubrication.

Advantages of plastic bushings over metal include low friction, non-reactive surfaces, and long life. CZPT offers a variety of engineering plastics that outperform traditional metals in a range of applications. For example, nylon bushings resist wear while requiring little lubrication. In addition, polymer-shaped plastics are lightweight and highly resistant to aggressive cleaning agents and chemicals.

Besides being less expensive than metal bushings, plastic bushings offer many other advantages. They are very durable, have a low coefficient of friction, and are more wear-resistant than metal. Unlike metal, plastic bushings do not require lubrication and do not absorb dust and oil like metal bushings. They are lightweight, easy to maintain and last longer. This makes them an excellent choice for many applications.

Sleeve bearing

Sleeve bearings are simple pipes with matching components. They facilitate linear motion by absorbing friction and vibration. They can withstand heavy loads and work at high temperatures for long periods of time. Flange bearings are similar to sleeve bearings, but are enclosed and rotated in a housing unit. Sleeve bearings have higher load-carrying capacity and resistance to shock loads. Furthermore, they are lightweight and low cost.

Another name for sleeve bearings is babbitt radial bearings. These bearings are usually made of bronze and have straight inner and outer diameters. They are also impregnated with oil and can withstand radial loads. Typical uses for sleeve bearings are agriculture, automotive and machine tools. Sleeves can also be solid or cored material, depending on the intended use.

The type of sleeve bearing used in the bushing is important in determining which type of bushing to buy. Sleeve bearings are sized based on pressure and speed considerations. Typically, the PV limit is an upper bound on the combined pressure and velocity for a given casing material. In some cases, the sleeve bearing used in the bushing is the same as the plain bearing.

Sleeve bearings are simple in design and made from a variety of materials, including bronze and plastic. They are more affordable than metal, but plastic is still not inaudible. Plastic sleeve bearings will rattle like metal bearings if the gap between the two bushings is not accurate. Additionally, high temperature electronic painting can permanently thin the casing. The stainless steel backing provides a good surface for electronic painting and enhances abrasion resistance.

editor by czh 2023-02-18